Page 1 of 1

Another thing to look at on my 648

Posted: Sun May 22, 2022 8:43 pm

by JSinMO

First the disclaimers:

1) I have no doubt this has been discussed 1000 times. Please keep in mind this is my first GT. And first time working on a hydraulic drive system.

2) ras101 has posted a similar topic on travel control, but my understanding is the 446 and 648 are set up different. If that is not the case please let me know and we can discard this post.

So now that I’ve started using the machine I notice it seems to have trouble moving on uneven ground. Part of the problem is I don’t know what the characteristics of the 648 or any similar tractor should be. I would put it at anemic bordering on gutless going up hill.

I got my first clue the other day backing it out of the shop. When I depressed the foot control I noticed the direction control lever moved on its own. I held the lever in place and had much better response and a much better pedal. It was soft with a lot of free travel before.

A quick check of the owner manual showed me this is a common adjustment point.

I’ve looked through the technical data here and read quite a bit online. It seems pretty straight forward. I see where the wear points would be. And how it should work.

You guys have made this repair before, I have not. What are the tips, short cut, things to know that a 1st timer wouldn’t pick up from looking at pictures and reading technical data.

Just like the power steering cylinder, I don’t think this repair is an emergency and may get put off till fall depending on how the other irons in the fire go.

This may come down to just needing adjustment, or, I may be rebuilding the linkage.

At this point I’m just gathering information, it makes it a lot easier for me when I’m actually turning wrench.

Thanks for taking a look and for you thoughts.

Re: Another thing to look at on my 648

Posted: Mon May 23, 2022 11:03 am

by Eugen

I'm following this with interest as this is something that I need to look into in the future!

Re: Another thing to look at on my 648

Posted: Mon May 23, 2022 8:50 pm

by JSinMO

I took a quick look underneath this morning and checked it out. The control plate seems to have quite a bit of play in it. I can move it quit a bit by hand. My first thought was to weld the egg shape holes shut and re drill them, but I don’t know, might be smarter to just get a new plate and linkage.

I adjusted the travel control lever per the instructions in the book, but it really didn’t help. The lever still moved on its own when depressing the foot lever. This indicated to me the friction disc is either well worn or nonexistent at this point.

I guess I need to decide how I want to make repairs and go from there.

Re: Another thing to look at on my 648

Posted: Mon May 23, 2022 9:48 pm

by Spike188

@JSinMO I have a new banana plate here and the 646BH bare frame on stands bottom side up. I might be able to get some pictures of the plate that will help you in the morning. These would be easier to adjust on a hoist but my method will be to do all of the bottom side assembly before flipping the frame. My Mrs says that she will be dead before it is finished because I haven't learned how to tell customers "No". I am learning slowly.

I put a new plate, linkage, and bushings on the 646L and have never finished the proper adjustment. Part of the reason is that the new plate is a bit thicker than the original and binds in the frame.

Spike

Re: Another thing to look at on my 648

Posted: Mon May 23, 2022 10:10 pm

by JSinMO

Spike188 wrote: ↑Mon May 23, 2022 9:48 pm

@JSinMO I have a new banana plate here and the 646BH bare frame on stands bottom side up. I might be able to get some pictures of the plate that will help you in the morning. These would be easier to adjust on a hoist but my method will be to do all of the bottom side assembly before flipping the frame. My Mrs says that she will be dead before it is finished because I haven't learned how to tell customers "No". I am learning slowly.

I put a new plate, linkage, and bushings on the 646L and have never finished the proper adjustment. Part of the reason is that the new plate is a bit thicker than the original and binds in the frame.

Spike

I gladly take any pictures and advice you can offer!

A hoist would be nice. My plan is to set the tractor on cribbing and slide underneath when go to make the repair. It always make me nervous laying under something that’s not supported good!

Your Mrs is probably right, mine tells me the same

I appreciate the info.

Re: Another thing to look at on my 648

Posted: Tue May 24, 2022 7:04 am

by Harry

When I replaced the control plate, Banana plate on my 646, I just jacked it up and supported it with jack stands. On my 644 I lifted it with the stabilizers on the rear and used the bucket to lift it up, then put jack stands under it. The I rebuilt the fame that was cracked by welding the frame and reinforcing it with custom made plates over the cracked areas. All welded in the overhead position. It took two days of hard work to complete.

Safety first boys. Always take the time to support it properly.

Keep the Peace

Harry

Re: Another thing to look at on my 648

Posted: Thu May 26, 2022 10:21 am

by Spike188

I have been cleaning shop and reorganizing because the banana plate parts were hiding.

The black plate is the new one with ball joints and a different moon profile.

But the biggest difference is the overall plate thickness.

When replacing the plate on the 646L I may have not opened the frame mount enough or did not get the mount angled correctly. Hopefully work on the 646BH will commence soon.

Re: Another thing to look at on my 648

Posted: Thu May 26, 2022 11:30 am

by JSinMO

Spike188 wrote: ↑Thu May 26, 2022 10:21 am

I have been cleaning shop and reorganizing because the banana plate parts were hiding.image.png

The black plate is the new one with ball joints and a different moon profile.image.png

But the biggest difference is the overall plate thickness.

When replacing the plate on the 646L I may have not opened the frame mount enough or did not get the mount angled correctly. Hopefully work on the 646BH will commence soon.

Thank you for the pictures and info.

So the new plate is thicker to accept the ball joints. I can see why that would bind on the frame mount without adjusting it.

Looking at all the pictures of yours and mine it appears the moon or banana cut out on the plate really doesn’t take the wear. The linkage points are the real problem spots. That kind of takes me back to my first thought of marking the center point welding them up and redrilling my existing plate.

It also make me think that while they work together the control lever moving on its own probably should be addressed first.

Dang it, now you’ve got me wanting to go tear into it!

I might have to move this up on my list of thing to do!

Re: Another thing to look at on my 648

Posted: Thu May 26, 2022 12:27 pm

by Eugen

This topic is timely and applies to me as well, the lever on my 644 gets stuck sometimes in Forward or Reverse, and it takes quite some wiggling to get that unstuck.

Re: Another thing to look at on my 648

Posted: Thu May 26, 2022 12:54 pm

by JSinMO

Eugen wrote: ↑Thu May 26, 2022 12:27 pm

This topic is timely and applies to me as well, the lever on my 644 gets stuck sometimes in Forward or Reverse, and it takes quite some wiggling to get that unstuck.

Sounds like yours may be worn more that mine. If you can get a couple of pictures of it maybe we can compare them all against spikes new one.

Re: Another thing to look at on my 648

Posted: Thu May 26, 2022 2:12 pm

by Eugen

JSinMO wrote: ↑Thu May 26, 2022 12:54 pm

Eugen wrote: ↑Thu May 26, 2022 12:27 pm

This topic is timely and applies to me as well, the lever on my 644 gets stuck sometimes in Forward or Reverse, and it takes quite some wiggling to get that unstuck.

Sounds like yours may be worn more that mine. If you can get a couple of pictures of it maybe we can compare them all against spikes new one.

I will do Jeff, when I get a chance, and post here. For some reason I think my plate is "home made"

Nothing wrong with that in itself, the PO seems to have done a lot of work on this tractor, and good work at that, although he did not seem fond of OEM parts

and I don't blame anyone for that. Not everyone can afford all OEM parts.

Re: Another thing to look at on my 648

Posted: Mon Jun 27, 2022 8:00 pm

by JSinMO

I wanted to get back to this because it’s getting

to be a PITA to hold the travel lever all the time.

I was informed by she who watches the bank book that currently there is no funding in the fiscal budget for the procurement of replacement parts for aged equipment. Then there was some mention of keeping food on the table and the lights on or some such, but I quit listening after she said “don’t spend money on old tractors right now”.

I decided I really couldn’t make it worse, so barnyard engineering is the plan.

Disassembly was pretty easy, and once apart some of the problems are evident.

The foot control hole and linkage hole are quite egg shaped. And what I think was the friction washer is worn out and crumbling.

I laid out where the center of the holes should be and welded the existing holes shut.

I marked the center points and re drilled the holes.

I have some friction washers already from another project so I’m going to size them for this application and see what happens.

That’s where I had to stop for the day. Hopefully I’ll be able to reassemble and try it out soon.

Re: Another thing to look at on my 648

Posted: Mon Jun 27, 2022 9:40 pm

by Eugen

Looks good @JSinMO , should work just fine. I'm sorry I simply forgot to take pictures of mine on the tractor. I'll try to remember and do that in the next few days.

Re: Another thing to look at on my 648

Posted: Mon Jun 27, 2022 10:14 pm

by Eugen

Don't know if it helps but here it is

Re: Another thing to look at on my 648

Posted: Mon Jun 27, 2022 10:28 pm

by JSinMO

Eugen wrote: ↑Mon Jun 27, 2022 9:40 pm

Looks good @JSinMO , should work just fine. I'm sorry I simply forgot to take pictures of mine on the tractor. I'll try to remember and do that in the next few days.

Thank you, I’m hoping it at least works better. No worries on the pictures. We all have a lot of irons in the fire!

Re: Another thing to look at on my 648

Posted: Mon Jun 27, 2022 10:30 pm

by JSinMO

Eugen wrote: ↑Mon Jun 27, 2022 10:14 pm

Don't know if it helps but here it is

C6B0C185-6164-4F90-90EE-9417E9A4D1CF.jpeg

CEE45A1E-723A-4335-A930-8C594CCC8528.jpeg

Wow, I can tell you the biggest difference is yours is way, way cleaner underneath than mine is!

Re: Another thing to look at on my 648

Posted: Sat Jul 02, 2022 9:35 pm

by JSinMO

I spent some time this evening continuing on this project. I reassembled the whole thing, it didn’t go back together as easy as it came apart! Once I had it together I moved the foot and control levers and it seems much better. I watched the valve move while pushing the foot lever with my hand. It looks like I have full forward now, however I still don’t have full reverse. Watching it move it looks like I may have some wear in the banana cut out that I can’t do much about, but I noticed play in the ball linkage. I suppose I should have figured on that. I disassembled most of it again and took the linkage out. Yup it’s wore out.

But there is one on the other valve under there that is capped off for the rear lift that has never been used. Pulled it out and it feels much more solid with no play.

- You can really see the difference in wear.

So next time I’ll swap the linkage and reinstall everything.

Hopefully I’ll be driving it again soon!

Re: Another thing to look at on my 648

Posted: Sun Jul 03, 2022 9:50 am

by Eugen

Jeff, good progress, hope to see you back in the saddle soon. I never took mine apart as far as you but I'm sure mine has wear and needs attention. Helps to see what you're dealing with here!

Re: Another thing to look at on my 648

Posted: Sun Jul 03, 2022 3:27 pm

by JSinMO

I really wanted to see how my repairs worked so I went up this morning and put it all back together.

I pulled it out of the shop and made a few final adjustments.

I think we’re good to go! Now I have full forward and reverse with out holding the control lever!

I used a throttle friction disc to replace the friction washer on the control lever. We’ll see how long it lasts but so far so good!

So now it’s back to running it and see how it does!

Re: Another thing to look at on my 648

Posted: Sun Jul 03, 2022 5:31 pm

by ssmewing

Spike188 wrote: ↑Thu May 26, 2022 10:21 am

I have been cleaning shop and reorganizing because the banana plate parts were hiding.image.png

The black plate is the new one with ball joints and a different moon profile.image.png

But the biggest difference is the overall plate thickness.

When replacing the plate on the 646L I may have not opened the frame mount enough or did not get the mount angled correctly. Hopefully work on the 646BH will commence soon.

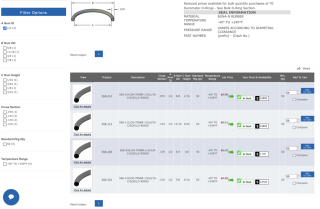

The thicker banana plate is only generally sold with the needed matching mounting bracket.

https://salempwr.com/c48640-kit-c21512-replacement/

https://salempwr.com/c48638-kit-cam-assy/

Whoever posted the picture of their banana plate that did not have the same amount of paint wear or contact with the follower in the slot, does not have the mount in the exact plane that the control lever travels. That is an essential adjustment for optimal operation. That can cause jamming and uneven wear. Uneven wear means it will wear out faster.

The last tip is the one that will tell you when you have a like-new travel control, the foot pedal should stop short of the floorboard.

Re: Another thing to look at on my 648

Posted: Sun Jul 03, 2022 6:42 pm

by Spike188

Thanks for the post

@ssmewing. Now I can stop looking for the mounting bracket to post a picture of. It is buried somewhere in my clutter and will probably show up this week then get lost again.

Re: Another thing to look at on my 648

Posted: Sun Jul 03, 2022 7:18 pm

by JSinMO

The last tip is the one that will tell you when you have a like-new travel control, the foot pedal should stop short of the floorboard.

[/quote]

Thanks for the tip. I think I got it pretty close. Before the foot pedal would go all the way to the floor. Now it is as you stated, it stops short of it.

Re: Another thing to look at on my 648

Posted: Sun Jul 03, 2022 9:58 pm

by Eugen

Likewise thank you for the tip @ssmewing , mine travels to the floor. Now I know how it should be.

Re: Another thing to look at on my 648

Posted: Sun Feb 25, 2024 8:21 pm

by JSinMO

I figured I’d continue this thread just to keep my work on the 648 together.

It’s leaking hydraulic oil so bad at this point it’s basically useless so time to pull it in the shop.

I’d like to get a couple of housekeeping item out there before I jump into this.

First, this is NOT going to be a tutorial! This will be the first time I’ve ever worked on hydraulic cylinders, I’ll be learning as I go! I’ll probably do more things wrong than right, but I really want to gain the knowledge and ability to work on stuff like this, and the way that works for me is to get my hands on it! On that note hanging around with you all has helped me gain the confidence to try something new, even though it feels a little daunting, so thank you all!

Secondly, I have been in contact with Bob

@myerslawnandgarden and Ryan

@CaseIngersollNE and I want to say these are very knowledgeable, very helpful fellas! It’s really nice to have people that have the experience and willingness to help. If you haven’t done business with them you should! Thank you guys I appreciate it!

Now on with the tomfoolery!

The quick and dirty backstory on this tractor is that I stumbled upon it sitting under a guys back porch and I had to have it! It had sat uncovered, non running for 10 years. If you want to see more of the story of what we have done so far you can find it here.

viewtopic.php?f=4&t=702

The power steering cylinder is leaking so bad I leave a trail of oil everywhere I go so it has to be addressed. Unfortunately at this point there is no kit readily available to rebuild it. Ryan is looking into it so fingers crossed on that. The lift and dump cylinders are also leaking and I decided I’m going to go through them all and have the tractor done. I’ll worry about the backhoe later. It not as bad at this point.

Today we will be doing some exploratory surgery.

Everything is covered with dirt and oil so some disassembly and cleaning will be my first step.

I took the bucket cylinder off partly to figure out how to get it apart, and partly to stop it from dripping.

The lift arms and bucket cylinders all have snap rings but the power steering cylinder needs a gland wrench and I don’t have one so I decided to make one.

I basically cut a fork out and welded roll pin to it. This is the unholy piece of barnyard butchery I came up with!

I suppose I don’t have to say it didn’t work! As soon as I put pressure on I bent it.

I’d have to make something heavier for sure. I’m going to have to see if I can find a spanner made for this.

You can see the seal on the power steering cylinder is very messed up! It’s hard as a brick and looks to be pushed out of position.

After clean up I can see the seals are wet and leaking.

With everything cleaned up that’s where I stopped for today. I’m not going to try and take cylinders apart until I get parts in.

Re: Another thing to look at on my 648

Posted: Sun Feb 25, 2024 11:07 pm

by RoamingGnome

Looking forward to reading more of your 648 repair adventures.

My Case 530CK (the full size backhoe) basically leaks from every hose, cylinder and orifice possible. The valve under the steering wheel is leaking so badly I wore a pair of rain pants the last time I moved it. I've promised myself not to start playing with it until I get the steering valve resealed and all the cylinders off and repacked.

Re: Another thing to look at on my 648

Posted: Sun Feb 25, 2024 11:29 pm

by CaseIngersollNE

Thanks for the kind words and shut out. Glad to help and looking forward to seeing your progress! We will be talking soon.Ryan

Re: Another thing to look at on my 648

Posted: Mon Feb 26, 2024 6:53 am

by DavidBarkey

@JSinMO Take a real close look for any pitting on the shafts that will pass the seals when retracted all the way . That will need to be addressed before new seals . Hopefully all the cylinders were fully retracted when parked before you got it and it's just old hard seals .

Re: Another thing to look at on my 648

Posted: Mon Feb 26, 2024 3:50 pm

by Eugen

@JSinMO I have pretty much explained a sure way of getting the right size of all the seals you need, when a kit does not exist. I have done this on all the cylinders I have repacked: all cylinders on my old 644, plus one cylinder on my current 644, and two cylinders on the big case, plus all cylinders on my D100 backhoe. Honestly, it's really easy. All you need is a $25 caliper which you'll keep for many years anyway, if you don't have one. If you'd like more details let me know, just trying to help.

Re: Another thing to look at on my 648

Posted: Mon Feb 26, 2024 5:27 pm

by Jancoe

I'll look up my notes. I believe there was 2 different cylinders used on the 648. The later is the same as the 6018 one. I have aftermarket seal numbers for that later cylinder.

Sent from my SM-S906U using Tapatalk

Re: Another thing to look at on my 648

Posted: Mon Feb 26, 2024 6:40 pm

by JSinMO

@Jancoe Thank you. I have think this is either a 1980 or 81 and has the earlier style.

@Eugen Yes please. I’m sorry I had forgotten that you had posted that information. If I’m telling the truth I’m pretty apprehensive about this project and I’m not sure why. I guess it’s a combination of being the first time for this and not wanting to get the wrong parts. I’ve order the seals for the lift cylinders and bucket tilt already so the power steering is the only one in question. Thank you.

@RoamingGnome That made me grin! Putting on rain gear to run the tractor is dedication!

Re: Another thing to look at on my 648

Posted: Mon Feb 26, 2024 8:05 pm

by RoamingGnome

@JSinMO I'm glad I was able to make you grin, the valve is right under the steering wheel, so it pours into your lap, and then down into your boots

Good Luck with your repairs, don't worry too much about the cylinders, once you get one open you'll see it's not that scary, and gets easier and less stressful with practice. As David mentioned check the chrome surface on the rods when you have them apart, you want to make sure it's nice and smooth so nothing will catch on your new seals

The sad thing about my big backhoe is that the steering wheel is stuck on and won't come off -

I had heated it red hot trying to get it to move. I think my next step is to take a zip cut and slice the hub so that I can work it off the splines...

Re: Another thing to look at on my 648

Posted: Mon Feb 26, 2024 9:14 pm

by JSinMO

@RoamingGnome Thank you Gerry, I appreciate that.

And I feel you pain on that steering wheel!

I heated, and soaked, and beat, and had a puller on this one. I was down to cutting it like you said and it finally popped loose! It put up such a fight I hung it on the shop wall like a trophy!

Re: Another thing to look at on my 648

Posted: Tue Feb 27, 2024 11:08 am

by Eugen

By all means, please do what you're comfortable with. I just wanted to remind you of this road taken before. My only other comment is that you may consider getting seals for all the cylinders because they tend to fail in the same time period, and thus you may save on shipping.

Re: Another thing to look at on my 648

Posted: Tue Feb 27, 2024 1:10 pm

by Harry

Jeff, I found when I ordered a kit for the rebuilding of the bucket tilt cylinder, they gave me more than what was needed and some were of no use at all. I figured that is why the price was so high. My next rebuilding adventure was the cylinders for the 644 backhoe. I disassembled one and found a local hydraulics shop. They matched them for me and I purchased for all three boom cylinders which were all the same size. Cost for all three was less expensive than for one kit of the bucket cylinder. I will use this local shop for all future cylinder projects.

Harry

Re: Another thing to look at on my 648

Posted: Sat Mar 02, 2024 2:48 pm

by JSinMO

Thanks

@Eugen and

@Harry I’m sure you guys are right about measuring and ordering seals but I just felt more comfortable getting kits for my first time around. I will probably try it on the next go round!

I guess I’ll call this update success and failure as there were some of each!

I wasn’t happy with my effort making a spanner for the power steering cylinder, so I tried again. Here is spanner 2.0

I cut it out of steel and used old roller bearings for the pins. I had a good feeling about it but I just can’t get a good grip on the gland. I guess this proves I’m not a tool and die maker!

I don’t want to destroy the cap so that’s a hard stop till I get a tool but at least I tried!

I needed a small victory after that so I put a new pin in the stabilizer foot and got it mounted back on the tractor.

I decided to go ahead and disassemble one of the lift cylinders so I raised the loader all the way up and secured it with a chain and brace. It did make easier to work on.

After head scratching and look over the parts manual. I was able to take the cylinder apart relatively easily.

I did look over the all the cylinders and they look good to me. The chrome is shiny and I don’t see any pits or dents so I think there good. Knowing me though I decided it would be a good idea to protect them as I work on them to I cut a piece of pvc pipe and put it over the rod.

I’ll just do one at a time. I can see the seals are shot they are hard and it’s no wonder they were leaking. The tube look fine on this one, I don’t see any burrs or deformation so I covered it for now.

I ordered the new seals for the lift arms and bucket tilt last Saturday thinking I could put them in today but the US Postal Service has other plans!

they were supposed to be here by Thursday but didn’t show up. Now all there tracking says is “ moving through network, arriving late” . It looks like there somewhere in Missouri but not here yet!

That where I’ll have to stop till the postman can get them here!

It looks like a sad state of affairs at the moment, but it will be much better before long!

Re: Another thing to look at on my 648

Posted: Sat Mar 02, 2024 6:32 pm

by Harry

It’s a work in progress Jeff.

Looking good, slow and steady wins the race.

Harry

Re: Another thing to look at on my 648

Posted: Sat Mar 02, 2024 9:49 pm

by CaseIngersollNE

The USPS has been a disaster since the beginning of the year its crazy we have not had this many issues with shipping in a long time with the USPS...

Re: Another thing to look at on my 648

Posted: Sun Mar 03, 2024 1:48 pm

by myerslawnandgarden

Agree, USPS delivery times have been terrible lately. Even my brother in law who works for the post office is warning people to mail early.

Bob

Re: Another thing to look at on my 648

Posted: Mon Mar 04, 2024 7:22 pm

by JSinMO

I see what you guys mean, still no delivery.

Check out the tracking so far. No wonder the postal service runs at a deficit!

Re: Another thing to look at on my 648

Posted: Mon Mar 04, 2024 7:37 pm

by Timj

I just learned today that our area will no longer have an evening mail truck picking up from the Post Offices and taking mail to the regional sorting center. There will only be a morning run. Im going to have to figure out another way to get my water samples to the lab.

Re: Another thing to look at on my 648

Posted: Tue Mar 05, 2024 6:38 pm

by JSinMO

Hey Hey they finally got here!

Now I got to have time to go work on it!

Re: Another thing to look at on my 648

Posted: Tue Mar 05, 2024 8:20 pm

by myerslawnandgarden

Timj wrote: ↑Mon Mar 04, 2024 7:37 pm

I just learned today that our area will no longer have an evening mail truck picking up from the Post Offices and taking mail to the regional sorting center. There will only be a morning run. Im going to have to figure out another way to get my water samples to the lab.

Tim,

You might consider Spee-Dee Delivery since you're in Wisconsin as long as your lab is in their delivery area. They are expanding service into the Kansas City area April 8th.

Bob

Re: Another thing to look at on my 648

Posted: Tue Mar 05, 2024 8:46 pm

by CaseIngersollNE

JSinMO wrote: ↑Tue Mar 05, 2024 6:38 pm

Hey Hey they finally got here!IMG_4677.jpeg

Now I got to have time to go work on it!

Glad you got them, they were in you state 2 days from shippin CT and bounced around for a week....Insane!! And ridiculous

...

Re: Another thing to look at on my 648

Posted: Tue Mar 05, 2024 8:59 pm

by Eugen

JSinMO wrote: ↑Tue Mar 05, 2024 6:38 pm

Hey Hey they finally got here!IMG_4677.jpeg

Now I got to have time to go work on it!

Awesome!! Were you able to get a kit for the steering cyl?

Jeff, one thing I'd recommend, just to be on the safe side. I'm sure you got the right kits, but I tend to be on the cautious side and if I were you I'd take out the old seals and o-rings carefully and I'd compare them visually with those you got. It doesn't hurt to make sure they're the same size. Wish you an easy installation!

Re: Another thing to look at on my 648

Posted: Tue Mar 05, 2024 9:16 pm

by JSinMO

Eugen wrote: ↑Tue Mar 05, 2024 8:59 pm

JSinMO wrote: ↑Tue Mar 05, 2024 6:38 pm

Hey Hey they finally got here!IMG_4677.jpeg

Now I got to have time to go work on it!

Awesome!! Were you able to get a kit for the steering cyl?

Jeff, one thing I'd recommend, just to be on the safe side. I'm sure you got the right kits, but I tend to be on the cautious side and if I were you I'd take out the old seals and o-rings carefully and I'd compare them visually with those you got. It doesn't hurt to make sure they're the same size. Wish you an easy installation!

No I haven’t been able to get the power steering cylinder apart yet. I ordered a proper wrench for it and that is supposed to be here Thursday, then it’s just down to having the time to try it again.

Yes good point I will definitely be comparing the new seals to the old ones to make sure there good before it all goes back together!

Re: Another thing to look at on my 648

Posted: Wed Mar 06, 2024 8:11 am

by Harry

Eugen wrote: ↑Tue Mar 05, 2024 8:59 pm

JSinMO wrote: ↑Tue Mar 05, 2024 6:38 pm

Hey Hey they finally got here!IMG_4677.jpeg

Now I got to have time to go work on it!

Awesome!! Were you able to get a kit for the steering cyl?

Jeff, one thing I'd recommend, just to be on the safe side. I'm sure you got the right kits, but I tend to be on the cautious side and if I were you I'd take out the old seals and o-rings carefully and I'd compare them visually with those you got. It doesn't hurt to make sure they're the same size. Wish you an easy installation!

Yes, that’s an excellent

Eugen.

Harry

Re: Another thing to look at on my 648

Posted: Sat Mar 09, 2024 9:25 pm

by JSinMO

I had a a little time today to continue working on the 648. The tools I ordered came in so I had to try the gland wrench first thing.

The cap on the power steering came loose easily!

The gland is aluminum and I was worried about tearing it up. I’m glad I ordered the spanner. I would have like for my home made tool to work, but sometimes you just need the right tool! I decided not to disassemble it yet, i want to get the others done first and getting it loose was what I worried about.

I took the lift cylinder rod I already had out and chucked it into the vice. I used a block of wood to support it.

I was able to disassemble it with no problems and started cleaning thing up.

Looking over things I don’t think these cylinders have ever been apart before. There’s basically nothing left of the wipers but it seems the were some sort of fiber material.

I spent more time cleaning the parts than anything else! I also noticed the back up rings on the piston were a fiber material as well. Not sure if you’ll be able to see the difference between the old and new in this picture.

This is a job that certainly needed to be done. The old seals are all hard and misshaped. I’m very happy with the seal kits. They had everything I needed, including new retainer rings.

With the first cylinder reassembled I put it back in the tube.

I was able to fit it back into place without much trouble. And with that I finished my first cylinder rebuild!

I moved on to the other lift cylinder and started taking it apart. I had a small piece of hickory left over from when I made the pitman stick for the #39 sickle mover so I cut it into some wedges to use to tap the glands down to get the retainer ring out. They worked well.

I also rigged up a come along and chain to help put the rods out.

I got the second rod disassembled and cleaned. I noticed the tube on this one has a burr on it so I think I’ll borrow my

Dremel tool and sand it out.

That seemed like a good stopping point for today.

Hopefully I’ll be able to continue tomorrow and get most of this finished!

Re: Another thing to look at on my 648

Posted: Sun Mar 10, 2024 6:54 am

by DavidBarkey

@JSinMO Progressing nicely .

Re: Another thing to look at on my 648

Posted: Sun Mar 10, 2024 11:09 am

by RoamingGnome

@JSinMO Great update! Thanks for the story and photos

Re: Another thing to look at on my 648

Posted: Sun Mar 10, 2024 9:20 pm

by CaseIngersollNE

Great Job keep up the good work! Yes we add back up rings and both spiral retainer rings to our kits! I have no idea why they are not in the original kits.... Talk soon. Ryan

Re: Another thing to look at on my 648

Posted: Mon Mar 11, 2024 10:16 am

by Eugen

Good progress Jeff!

Re: Another thing to look at on my 648

Posted: Mon Mar 11, 2024 9:13 pm

by JSinMO

Thanks guys, it’s coming along!

I was able to finish up the lift cylinders and mark them off the list.

I moved on to the bucket cylinder but I had to change my rigging to get it into the right position to work on. A chain and a come along around a doubled rafter did the trick.

This one wasn’t as easy as the others. I had to get a bit more persuasive to get it to come apart. I used the 2N as an anchor point and rigged up a heavier come alone. With a strain on it and some tapping it finally came apart.

This one does have some dings in the rod, but I think it will be ok. I can see why it was leaking!

I put the new seals in and it reassembled into the tube fine so I thinks it’s good to go.

The bucket is a little tweaked I had to use a bottle jack to get the pins to line up.

With that done I went after the power steering.

It came apart easily.

No wonder it was spraying oil, the wiper is messed up and the seal inside is all but gone!

Ryan

@CaseIngersollNE has been working with me to get the seals together to rebuild this one. I really appreciate his help! Hopefully I’ll be putting this one back together soon!

It’s getting closer to being useful again!

@Eugen i wasn’t sure where your post on measuring and ordering seals was. I have cylinders on the bigger tractors that will need attention too. Do you have website you order seals from?

Re: Another thing to look at on my 648

Posted: Tue Mar 12, 2024 10:03 am

by Eugen

Great job on those cylinders Jeff! Oh, the rod that has damage. Normally that has to be smoothed completely otherwise it'll destroy your new seals. I used a sander for one of the rods where I had some small pieces of the chrome gone. The actual ding is not much of a problem, let's say you lose a tiny bit of liquid when the gland passes over it. It's the fact that it has a rough edge that's the problem, it will destroy the seal that keeps the pressure inside the cylinder, and possibly the wiper too. Hope this helps.

Here's the area of the forum where I talked about measuring the seals.

viewtopic.php?f=4&t=1043&start=160

Must be several pages around that area. I ordered my seals from

herculesca.ca

which I found is the Canadian version of

herculesus.com

The seals are of highest quality as far as I can tell, not made in China, and I found that Case had used all standard sizes seals, easily found in several versions on the site. Ask questions after you have a look at those pages, where I talked about, for instance, the hardness of the o-rings to get, etc.

Re: Another thing to look at on my 648

Posted: Tue Mar 12, 2024 9:34 pm

by JSinMO

@Eugen Thank you sir! I can’t believe I had forgotten the build you did and the amount of leg work you put in.

I honestly feel a little sheepish about it because now I remember thinking I need to save your thread for when I do mine!:30:

I think I about have the tractor cylinders done, unless I really screwed up and oil shoots every where! I still have the backhoe section, and at least two cylinders on big brother the 830 Case that will need attention. Now I’ve bookmarked this hopefully I can remember I did and refer to and you with questions!

Re: Another thing to look at on my 648

Posted: Tue Mar 12, 2024 11:06 pm

by myerslawnandgarden

Eugen wrote: ↑Tue Mar 12, 2024 10:03 am

Great job on those cylinders Jeff! Oh, the rod that has damage. Normally that has to be smoothed completely otherwise it'll destroy your new seals. I used a sander for one of the rods where I had some small pieces of the chrome gone. The actual ding is not much of a problem, let's say you lose a tiny bit of liquid when the gland passes over it. It's the fact that it has a rough edge that's the problem, it will destroy the seal that keeps the pressure inside the cylinder, and possibly the wiper too. Hope this helps.

Here's the area of the forum where I talked about measuring the seals.

viewtopic.php?f=4&t=1043&start=160

Must be several pages around that area. I ordered my seals from

herculesca.ca

which I found is the Canadian version of

herculesus.com

The seals are of highest quality as far as I can tell, not made in China, and I found that Case had used all standard sizes seals, easily found in several versions on the site. Ask questions after you have a look at those pages, where I talked about, for instance, the hardness of the o-rings to get, etc.

Thank you Eugen,

Very useful information, much appreciated.

Bob

Re: Another thing to look at on my 648

Posted: Wed Mar 13, 2024 10:43 am

by Eugen

Hope it's useful for you guys. I should've been more forthcoming with the detail so that people could do it easier for themselves when needed. I'm sure you'll be fine.

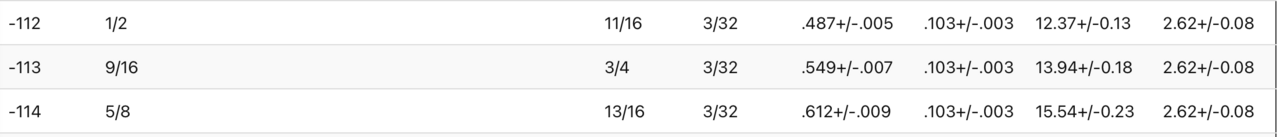

A couple of things that I think I forgot to mention. As I said before, I used a simple digital calliper for measuring the o-rings and seals. Sometimes the seals are completely destroyed so you cannot measure the diameter, but you measure the groove in which they sit, then you know the size. The beauty of the fact that standard AS sizes are used is that the groove or rod will give you the nominal size of the o-ring or seal, and that standard sizes are spread apart enough from each other so that measurement error is ruled out. For instance look at this below. The first column is the AS standard size. The second column is the nominal inner diameter (ID), third is nominal outer diameter (OD), and third is nominal cross section (CS). So, if the rod of a cylinder measures about 1/2 inch diameter as you can see in the picture below, the correct nominal o-ring would be 1/2" ID. The measurement error would have to be more than 1/16" to make the wrong decision for the o-ring. Same with the thickness (cross section) of the o-ring, in this example the distance between two standard sizes is 1/32" for thickness. A decent calliper and a little care when measuring will be enough to decide on the right size o-ring. I'll just add something that most of us knows, the nominal size of a o-ring is not the true measured size. For instance, if the nominal thickness of the o-ring is 1/16" a new o-ring will measure a little thicker. That's because in real life, in application, it needs to be compressed in order to provide a seal.

- Screenshot 2024-03-13 at 09.46.47.png (18.02 KiB) Viewed 1125 times

- Screenshot 2024-03-13 at 09.47.47.png (17.96 KiB) Viewed 1125 times

The site I used for looking up standard sizes for o-rings is this:

https://www.sealanddesign.com/technical/o-ring-sizes/

In my opinion is the easiest site to look up these sizes easily. But then, let's say we measured the rod and thickness of the old o-ring and our conclusion is that we need a 1/2 ID and 1/16 CS. Looking it up gives us a standard size of "-014". The site

herculesus.com

has several ways to look up o-rings. There is a drop down menu where I normally would choose Categories->Seals->Inch->Inch O-Rings and the website gives you these choices

Clearly the category I'm interested in is the 568 O-Rings, so I click on that and get another page with many types of 568 o-rings. This is where it gets interesting and here's where we choose the material the o-ring is made of. After some research my conclusion was to use 70 or 75 Duro Buna-N o-rings. 50 or 60 are too soft, and I did not see a reason to use 90, which are significantly harder. PTFE or Fluorocarbon are for more specific applications. So we click on the 70 Duro category and get a page with a list of many o-ring sizes of this hardness and some filters on the left hand side. I chose the 1/2" ID on the left hand side and that made the list smaller, like this.

Turns out that the o-ring that we want, with 1/16 CS is the first one on the list, which is product 568-014. So nice of herculesus.com, they keep the AS standard size as part of the product name. Once I figured this, for all other sizes of o-rings that I needed, once I figured the AS size, I would just search directly for "568-<size>" and that took me directly to the o-ring of 70 duro hardness of the size I need.

Backup rings are also interesting, they are used to give an extra back support to o-rings, so they are always on the opposite of the o-ring opposite to where the greatest pressure comes. They also follow the size standard. Once you figure this out it's pretty easy.

Re: Another thing to look at on my 648

Posted: Wed Mar 13, 2024 12:21 pm

by CaseIngersollNE

Glad to help, and glad the seals and cylinders on the loader went smooth, we will have this steering kit down one way or the other lol and will finally have a kit available for others to buy since Ingersoll has not supplied parts for it for a long long time and I do not think there was ever a "kit" for it. But we are changing that lol. Talk soon bud! Ryan

Re: Another thing to look at on my 648

Posted: Sat Mar 23, 2024 9:27 pm

by JSinMO

Well the USPS finally got around to delivering the seals for the power steering so I went about putting them in this morning. As I mentioned before I’ve been working with

@CaseIngersollNE to figure out what the correct ones are. They look like a good fit to me!

I have no idea how many of these early power steering cylinders are still out there, but now Ryan should have enough info to put a rebuilt kit together!

I put the cylinder back together and filled the oil tank.

I don’t know if any of you can relate, but for me this is the point in a project I get really nervous and the self doubt creeps in. Did I put everything together correctly? What did I miss? What if this, what if that etc. After thinking of everything I might have screwed up it was time to hit the key!

It’s alive, and no leaks!

After running the cylinders through their full range to bleed the air out and refilling the oil tank I went for a drive. I can’t put into words how happy I am to be driving around without leaving an oil trail behind me!

I think it’s time to put it to work and I have just the job!

I have ditches to help rain water run away from the driveway so it doesn’t wash out so bad. They need to be recut. I used the Kawasaki as a dump truck and hauled the dirt and sod over to continue filling in the ruts the propane guy left me. Everything worked great!

I have other chores I needed to do today but I was having so much fun I went up the hill be hind the shop and started clearing brush! I’m hoping to get this all cleared out and maybe plant some sunflowers here.

It was so nice to just be able to use the machine with out needing to worry about the oil running out!

Of course this is just another step in rehabilitating this tractor. The hoe will need attention next. The bucket cylinder has been leaking for awhile now. And after that it will be the hoses

Little by little I’m bringing this 648 back around. Hopefully over some time it will be a complete workhorse again!

Re: Another thing to look at on my 648

Posted: Sat Mar 23, 2024 10:29 pm

by RoamingGnome

Congrats on a job well done!

Looks like you had a good day for giving it a trial run too

I'm sure fixing the backhoe will seem even easier now that you have a little practice resealing cylinders.

Re: Another thing to look at on my 648

Posted: Sun Mar 24, 2024 7:08 am

by DavidBarkey

@JSinMO Well done . Yeah , I think we all experience self doubt the first couple of times .

Re: Another thing to look at on my 648

Posted: Sun Mar 24, 2024 1:28 pm

by THEOTHERHALF

congratulations on your success, it is motivation for others with the case ingersoll hobby, thanks for posting all the pictures, Kyle

Re: Another thing to look at on my 648

Posted: Mon Mar 25, 2024 8:16 pm

by CaseIngersollNE

Great job man! Knew you could get it done! And we are very glad to help! And thank you for the help and being the part of the R and D we have been needing to do this for awhile and this forced us to do it Lol. And Thanks To Bob at Myers Lawn And Garden For sending you my way as me and Bob are good friends and do a lot together and he knows we here have been working on all kinds of seal kits. So yes we will now stock a true seal kit for the early 648 PS cylinders, as far as I can tell there never was a "Kit" for these early ones, Just the later PS 648 cylinders. It was only individual parts you could get for the early and were not cheap, if I recall ONE of the seals alone was over $40 form Ingersoll when they were last available and I do not think they have been available for a very long time. But now they are! We will have them at

caseingersolltractors.com very soon along and we have another kit we are in the final stages of that we are very excited about being able to offer soon! Thanks Ryan

Re: Another thing to look at on my 648

Posted: Tue Mar 26, 2024 12:58 pm

by Eugen

@JSinMO I had quite a bit of self-doubt on my first two cylinders or so, so I know how it feels and I think it's normal when you don't do something very often or when you do it for the first time. I'm really glad it all worked out well and your machine is back to normal.

It's also very nice to see people are helping each other!

Re: Another thing to look at on my 648

Posted: Wed Mar 27, 2024 9:14 am

by Harry

Working on hydraulics can be a daunting experience for sure. You have to jump in and get it done. Sometimes experience is the best educator.

Harry

Re: Another thing to look at on my 648

Posted: Thu Mar 28, 2024 9:24 pm

by JSinMO

Well I wanted to do some work clearing this area out.

This is the place I’d like to plant sunflowers with the hope they will draw in game birds for hunting and this fall. I kinda have to get moving on it, I need to plant by late April to have whatever plants that grow ready in time.

I went up and started digging the honey suckle out with the 648 and it was working well, but the cylinder for the bucket is leaking and I just couldn’t stand it.

Back into the shop with it!

You guys were right. I feel much more comfortable dive into this now that I’ve done a couple. I had it apart pretty quickly.

I found a shop a couple towns over that said they could size everything up so I got the seals gland and piston in a box. Hopefully I can get seals tomorrow and slap it back together tomorrow night.

Re: Another thing to look at on my 648

Posted: Fri Mar 29, 2024 7:45 am

by Harry

All three cylinders on the boom should be the same. When I did mine I did them all at the same time.

Harry

Re: Another thing to look at on my 648

Posted: Fri Mar 29, 2024 10:04 pm

by JSinMO

Harry wrote: ↑Fri Mar 29, 2024 7:45 am

All three cylinders on the boom should be the same. When I did mine I did them all at the same time.

Harry

You are correct. I did go ahead and seals for all three. Just don’t know when I’m going to put them all in yet.

Re: Another thing to look at on my 648

Posted: Sat Mar 30, 2024 10:58 pm

by JSinMO

Well fellas spring seems to be upon us around here and the long list of things to do to get ready for summer isn’t getting shorter. But I wanted to start the day digging with the 648 for just a little bit. Kind of a test and tune to see how my repairs did. Things escalated quickly from there and the day turned into a full on deforestation operation!

For anyone reading this that’s thinking about getting into the GT world one of these Case tractors really should be at the top of your list! This is the first time I’ve gotten to spend a full day working this tractor and doing a lot of digging. I must say I’m very impressed!

I ran the engine at about 1/4 throttle and that was more than enough, plenty of power!

I dug out several stumps with no problem!

The tractor ran great all day!

I got big brother out to work as the dozer to move brush out of the way.

And the 2N got a workout grading the ground off.

All and all a very enjoyable day!

I do have a couple of items that will need to be addressed for repair after working every thing.

I quickly knocked the muffler off the 830 running through the brush.

if you ever see my tractors you’ll notice they all have floppy mufflers and this is why. I’d much prefer to break a loose muffler when a tree limb hits it than an exhaust manifold with a muffler secured to it that won’t move!

Secondly the 830 now has leaking cylinders on the loader!

Glad I just learned how to repair them!

Lastly and most importantly I noticed the left stabilizer wouldn’t retract, it would run down but not up.

I tied it up and ran back to the shop.

I disassembled the stabilizer and found the cylinder rod had broken where it pins to the foot!

I think it can be welded but it’s beyond my capabilities. I have a couple of friends that are much more experienced so I’ll have to ask them if they will help me weld it back up.

Even with a few hiccups I would call today’s operation a resounding success! I’m wore out but what a great way to spend a day!

Re: Another thing to look at on my 648

Posted: Sun Mar 31, 2024 10:34 am

by RoamingGnome

Thanks

@JSinMO It's great to see photos of your backhoe at work, I wish they weren't so rare in my area. Looks like you had a really productive day

I'll have to keep looking - one would make a really good addition to the collection of Case tractors up at the property...

Re: Another thing to look at on my 648

Posted: Sun Mar 31, 2024 9:06 pm

by Eugen

Digger action is the best Jeff, awesome!

Sucks about the stabilizer rod but it's not too bad a repair. My old stabilizer rods were in bad shape and I had two new made. But one of the old ones had the bottom piece broken and welded on and it seemed to be like that for many years. That was not the reason I made new ones though, it was because the chrome all the way up was damaged. I'm sure you'll have it fixed and it'll work good for many years.

Re: Another thing to look at on my 648

Posted: Sun Apr 07, 2024 10:01 pm

by JSinMO

Well after talking to a couple of friends I decided I wanted to try and repair the stabilizer cylinder rod myself. I figured the worst than that can happen is it won’t hold so why not try.

I started by grinding a V into the area to be welded.

I didn’t get a picture but I was fairly happy with the weld, but I thought it would be a good idea to give it some added support so I made a saddle to go around the area and drilled some holes to plug weld it in.

I also wrapped the rod in a wet cloth as I welded. After I was done I gave it a shot of paint so maybe it won’t rust as fast. Your criticism won’t hurt my feelings, I know it looks terrible, but I’m learning and it seems like it will hold!

I reassembled everything and now I have two working stabilizers again. How long will it last? Your guess is as good as mine! Maybe 4 days, maybe 40 years!

Re: Another thing to look at on my 648

Posted: Sun Apr 07, 2024 11:20 pm

by RoamingGnome

Looks sturdy enough -

Reminds me of the old days working out of a service truck - "Repairs designed in the field, hammer to fit, grinder for finish and paint to match..."

Re: Another thing to look at on my 648

Posted: Mon Apr 08, 2024 7:03 am

by DavidBarkey

Should hold . All the pressure should be down unless the foot is on very uneven ground prying sideways on it .

Welding supplies for the home welder that are a must have on hand for things like that .

Old copper pipe and header rap . The old copper pipe can be cut and made into different diameters to backup weld areas to maintain shape of hole while still getting full penitraion . Header rap with clamps well protect nearby surfaces . It can be wetted down to keep as well .

Re: Another thing to look at on my 648

Posted: Mon Apr 08, 2024 6:38 pm

by JSinMO

RoamingGnome wrote: ↑Sun Apr 07, 2024 11:20 pm

Looks sturdy enough -

Reminds me of the old days working out of a service truck - "Repairs designed in the field, hammer to fit, grinder for finish and paint to match..."

Yup you hit the nail on the head! That’s exactly what this process was!

@DavidBarkey Great ideas. Headed wrap never dawned on me I used a wet rag and kept checking the rod to make sure it wasn’t getting too much heat.

Re: Another thing to look at on my 648

Posted: Wed Apr 10, 2024 4:33 pm

by Eugen

Good repair Jeff! It's going to last a lot longer than 4 days for sure!

!

I used a wet cloth when I welded my rod eyelets too. Worked good.

Re: Another thing to look at on my 648

Posted: Wed Apr 10, 2024 9:36 pm

by Harry

You can read about it and watch others do it, but the only way you can get good at is to jump in and do it. Keep up the rod burning.

Harry

Dremel tool and sand it out.

Dremel tool and sand it out.