Page 1 of 1

Case D100 backhoe

Posted: Fri Mar 24, 2023 7:19 pm

by thebuildist

So I have a possible line on a Case D100 backhoe attachment from a Case trencher. It's what I consider to be very inexpensive. Cheaper than I'd pay to buy steel and cylinders.

It does have some kind of control levers, but it doesn't have any kind of outriggers or a place to attach a seat.

Obviously I'd need to fabricate some kind of mount with a subframe, etc, and rework this hoe's attachment frame to match. I'd try to work out some kind of a removable deal, where the whole underslung subframe can be easily removed. And I'm already piped to send it hyrdraulic flow.

So I feel confident enough about that part of it. But: Are my (non-gusseted) axle tubes strong enough to haul the dead weight around? If I need to reinforce them myself, how confident are we that they're cast steel, not cast iron?

And I guess I'd need to fabricate some outriggers and work them into the mounting area.

Anything else I need to think about before I take the plunge?

Bob

Re: Case D100 backhoe

Posted: Fri Mar 24, 2023 7:28 pm

by MattA

Bob this is what the transaxle in my 2001 4016 looks like. It's also got slightly different gearing. If you need more pictures or measurements let me know.

Re: Case D100 backhoe

Posted: Fri Mar 24, 2023 7:34 pm

by thebuildist

Re: Case D100 backhoe

Posted: Fri Mar 24, 2023 7:58 pm

by Eugen

The down riggers should be part of the frame on which the backhoe is connected. Look carefully. Did you see the pics from my trencher that has the D100?

Re: Case D100 backhoe

Posted: Fri Mar 24, 2023 8:15 pm

by JSinMO

@thebuildist I can’t help you with the axel questions, but some other things came to mind.

My 648 has the D100 backhoe with vertical stabilizers like this.

They do work, but I think an outrigger style would be more stable and maybe better at preventing tipping when swinging the boom. I’m really aware when I’m moving the boom side to side to make sure I’m not getting in trouble.

The other thing I thought of is weight. Here is the difference between the D100 with vertical stabilizers and outriggers.

My backhoe weighs in at 810LBS without the bucket, not sure what it weighs. The subframe on my tractor has a 500LBS counter weight built into the front of it under the front of the tractor. The front end of the tractor is still very light. It takes very little to get the front wheels off the ground when traveling.

1) A subframe with counter balance may be difficult to make quick disconnect.

2) I’m not sure of the differences between my 648 and your tractor, but since I know my front end is still too light, would a quick disconnect subframe with no counter weight, and a bucket mounted counter weight be better? That would get the weight farther out in front of the tractor and hopefully balance it better.

Just some things I thought of.

@Eugen added the backhoe manual to the technical library here some time back. It should have a lot on info in it for you.

Re: Case D100 backhoe

Posted: Fri Mar 24, 2023 9:26 pm

by thebuildist

Here's what I know about it until Monday:

As far as I can tell, that seems to be one of these:

https://www.bigiron.com/Lots/DavisCaseI ... Attachment

which has a big, beefy attachment frame, but no downriggers that I can perceive. So I presume I'll have to fab a set.

Thoughts on the need for reinforcing axle tubes, and how easy or difficult it'll be? If it's steel, I can weld in some gussets from 1/2" plate steel. If it's cast iron, I'll have to braze them in, which is a way more involved process.

Re: Case D100 backhoe

Posted: Fri Mar 24, 2023 9:40 pm

by Harry

Bob, sounds like a huge project to me, but I figure your the guy who can get it done from what I’ve seen from projects you have completed. I’ve always found myself that I have been tempted in buying something that is a big project for me. For myself I’m better off waiting until something more feasible comes along. I just have to play the waiting game until it does. Just my two cents.

Harry

Re: Case D100 backhoe

Posted: Fri Mar 24, 2023 11:00 pm

by Spike188

Bob, Around here the D100's in working condition asking price is $4000CD. I agree with Harry that this is a big project. From the pictures on your link it appears that the down riggers are not in the tubes. This makes me wonder if the down rigger cylinders and related piping is also missing. As far as under carriage and counter weights go, they can be fabricated with flatbar and slab plate.

The BH tractors came with webbed rear axles for added strength to carry the added weight of backhoe. There would be considerable stress on the axles when the hoe bucket was full of dirt while moving the tractor with its light front end.

Re: Case D100 backhoe

Posted: Sat Mar 25, 2023 2:04 am

by Jancoe

Honestly I wouldn't put that heavy backhoe on your tractor. I know you've beefed up the frame and what-not. But a 4000 series with a d100 will drag your machine around and bounce the front end off the ground. You would have to make and extremely sturdy sub frame. I think if you do decide to buy it you should re sell it and buy something lighter and a hair smaller.

Sent from my SM-S906U using Tapatalk

Re: Case D100 backhoe

Posted: Sat Mar 25, 2023 7:17 am

by DavidBarkey

@thebuildist Bob all the welding to web the rear axle would put a lot of internal stresses on the axle and possibly pull it out of align so as it would need line boring on the tubes . As for the D100 , why not make it tow able but still use your machine to anchor the front and power the hydraulics . Once in position outriggers would fold down and lift it off the wheels .

or self propelled like this .

food for thought

Re: Case D100 backhoe

Posted: Sat Mar 25, 2023 7:29 am

by thebuildist

I appreciate the honest feedback.

It seems like I'd be crazy not to buy it. But I also might be crazy to try to install it. Like @Jancoe pointed out, it's bigger than I really want. And the last thing I want to do is snap my transaxle in half.

So it seems like I'd definitely have to reinforce my axle tubes. I'm sure I've heard someone, maybe on the other site, insisting that the transaxle (or is it the front axle?) is made of cast steel, not cast iron. But I can't recall for sure.

So either I pass on it, or I buy it and try to resell it/trade it for something smaller, or I buy it and plan to install it, including building my own outriggers and reinforcing my rear transaxle.

What's the weight limit on my turf tires? Anybody know offhand?

Bob

Re: Case D100 backhoe

Posted: Sat Mar 25, 2023 7:47 am

by Eugen

FWIW, the bucket, boom, and dipper are not that heavy. I took the dipper + bucket off of mine and can push them on the ground easily. The square element that the left-right moving assembly is part of looks like it's as heavy as the rest all together. Maybe you can use just the boom dipper and bucket an make your own left right swing mechanism.

As for the rear axles, how about a bolt-on reinforcing brace using half inch plate? Is the webbing on the transaxle of the 646lbh is thicker than 1/2"?

Re: Case D100 backhoe

Posted: Sat Mar 25, 2023 9:00 am

by thebuildist

So maybe when I make the subframe, instead of slinging the rear end from the 3pt hitch frame, I instead build a heavy duty hook bracket (3/4" or even 1" plate) and have those hooks hang from the axle tubes right out at the outer bearing. That bearing has to hold the weight regardless, but this way there's almost no bending pressure put on the axle tubes. I'll have to work out a way to get it to be stationary, so that it can't move up/down/left/right once it's in place. Should be doable, and still easy to remove.

That also lets me leave the 3pt hitch installed, which speeds up installation/removal.

Then the question is, are my actual wheels and tires up to the job? Right around 1000lbs hanging about 36" behind the axle, with enough weight in the front to counter it means surges of at least about 2500 lbs hanging from the rear axle outer bearing housings And surges of up to about 1500 lbs on either rear tire. As I say, I think the outer housing and bearings are up to the job. Are the rear wheels/tires going to stand up to that?

Bob

Re: Case D100 backhoe

Posted: Sat Mar 25, 2023 10:23 am

by JSinMO

Bob, you certainly have much more knowledge, experience, and talent than I do at fabricating this sort of thing so I hope you don’t mind my questions.

Wouldn’t you have to also tie the axel to the frame to negate that same force horizontally? Or would welding a bar across the piece you drew up be sufficient?

I don’t know if this will be helpful to you but here are some pictures of my subframe.

My backhoe is attached to the subframe with 4 pins, but that could be converted to 3 point fairly easily.

The subframe with counter weight is bolted to the tractor frame.

I can’t think of a reason that your wheels wouldn’t handle that weight. I think the stiffer your sidewalls are on the tires the better. Might need a heavier ply tire?

Re: Case D100 backhoe

Posted: Sat Mar 25, 2023 10:27 am

by Eugen

Very valid points Jeff! Also thank you for posting these pictures

@JSinMO very useful for me too!

Went out and snapped a couple of pics of that boom and stabilizers, maybe helpful I don't know.

Re: Case D100 backhoe

Posted: Sat Mar 25, 2023 4:19 pm

by thebuildist

@Jancoe

I'm thinking of something along this general line:

https://images.app.goo.gl/Ft37CEDDecT2YYeU8

The long rails I'm thinking would be made of steel plate, about 4 in high. And either half or 3/4 in thick.

You would back up over the rails end up against the main backhoe frame.

The front end of the frame would have to have grooves where it could engage some pins and still slide forward and backward. For that I'd weld or bolt some kind of ears or shackles under the frame up front. Or even attach something to the snap fast pins.

But you'd back up just far enough to engage the front of the frame in these sliding grooves. Then hook up the hydraulics and push the hoe boom down. Which would have the effect of lifting up the rear axle hooks/shackles.

The more I think about it, the more I think I would build some square cast iron collars that are split in the center and have a hole the same diameter as the outer axle tubes.

So those heavy square collars would be permanently bolted around the axle tubes. And it would spread the load over a larger area of the axle tube itself, and prevent a pinpoint load. And then the hooks that I drew in the picture would actually be heavy horizontal shackles that will slide forward over those square collars.

So push the boom down which will lift the backhoe frame and rear shackles up in the air and once they're the proper height then push the dipper out away from you and that will push the whole subframe and shackles forward to engage those square collars. Then drop in a couple vertical pins to lock the shackles around the collars. And a couple heavy horizontal pins up near the front sliding grooves.

At that point it's tied heavily/firmly to the rear axle. And it's locked parallel with the tractor frame by the front pins. It can jiggle but not move.

I don't think it should be too technically challenging. The hard part is tracking down the 3/4 plate.

For a front weight it's pretty hard to get significant weight under the front axle up there. There's just not a lot of space to put it. If you put it between the front tires, then there's limited volume. That's where a big iron casting would come in handy. But I don't have the wherewithal to do that.

I do have a 400 plus pound front weight bracket that attaches to the snap fast. It's a steel bracket that holds a total of six two inch by 4 inch by 48 inch steel weights in a horizontal fashion as if it's a front bumper. But it sticks out pretty far and I think would be struck by the bucket.

I could sling those weights crosswise under the frame behind the front wheels, essentially where the deck is at now, but being behind the front wheels doesn't do much to counter all that leverage that the hoe has. So I don't think that's workable.

It would be great to attach a smooth 1" piece of plate steel to the bottom face of the loader bucket. The bucket would still be usable, albeit with less lifting capacity. That plate would weigh around 250 lbs and be 5.5 feet from the rear axle. That plus the current weight of the loader structure I think would adequately counterbalance the hoe. Not overkill, but enough.

But it would be a little tricky figuring out how to attach it, and pretty expensive.

For free I could just build some brackets where I could attach my current counterweight pieces. There are six pieces that weigh around 65 lb each. So I could mount two or three of them vertically to each of the outer lower faces of the loader boom. Two each side would probably be plenty. But if not two then surely three would do the trick.

It might look a little janky, but it should work fine, and the hoe wouldn't be installed terribly often.

That leaves the final need to create outriggers. It seems to me that for the cost and the complexity, that winged outriggers give you a lot more bang for your buck, because they spread your load out sideways and make the tractor less tippy to the left and right. I don't think they weigh any extra. And they wouldn't cost any extra to manufacture. So that's probably the direction I will go.

My final concern is the hydraulic reservoir volume. How big is the reservoir on an LBH model?

Bob

Re: Case D100 backhoe

Posted: Sat Mar 25, 2023 7:25 pm

by JSinMO

As usual Bob you have a very well thought out plan. I would expect no less! I think you’re right, finding a good way to get the counter weight out at the bucket is the way to go. My belly weight starts 2 feet forward from the center line of the rear axle and ends 4 1/2 feet from the center line of the rear axle at the front of the tractor and it seem to be a little light.

According to the manual my 648 lbh has a total capacity of 13 quarts of hydraulic oil, at a flow rate of 9 gallons per minute at 3600 RPM.

I hope the deal for the backhoe works out for you on Monday. If it does, I look forward to the build!

Re: Case D100 backhoe

Posted: Sun Mar 26, 2023 11:27 pm

by Eugen

The parts manual for the 644 loader and lbh shows two different part numbers for the axles. Does anyone know if the axle of the lbh is larger diameter?

Re: Case D100 backhoe

Posted: Sun Mar 26, 2023 11:51 pm

by Jancoe

Yes the backhoe models have 1.5" longer shafts. The shaft diameter at the outside bushing is larger than the inner bushing. I replaced my bh axle bushings a while back and saved my old bushings for referencing if I ever needed. I'll have to take a look to see how much bigger. I'm thinking it was 1/4" larger.

Sent from my SM-S906U using Tapatalk

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 12:02 am

by Eugen

Jancoe wrote: ↑Sun Mar 26, 2023 11:51 pm

Yes the backhoe models have 1.5" longer shafts. The shaft diameter at the outside bushing is larger than the inner bushing. I replaced my bh axle bushings a while back and saved my old bushings for referencing if I ever needed. I'll have to take a look to see how much bigger. I'm thinking it was 1/4" larger.

Sent from my SM-S906U using Tapatalk

I don't really understand this stuff with the bushing, sorry. Is the actual axle thicker?

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 12:13 am

by Gordy

Bob,

As to the question of the axle being cast steel or cast iron. I have been told it is steel and recall seeing them welded after the differential bolts broke and punched a hole in the axle housing. But it is easy to confirm this, pick an out of sight spot and drill a 1/8" hole a 1/8" deep. Collect the material the drill removes. You know steel holds together and is shiny silver, cast iron will be small flakes and powder with a dull grey color. If you don't want to use a drill, a coarse file should work too.

Gordy

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 8:30 am

by Timj

Gordy wrote: ↑Mon Mar 27, 2023 12:13 am

Bob,

As to the question of the axle being cast steel or cast iron. I have been told it is steel and recall seeing them welded after the differential bolts broke and punched a hole in the axle housing. But it is easy to confirm this, pick an out of sight spot and drill a 1/8" hole a 1/8" deep. Collect the material the drill removes. You know steel holds together and is shiny silver, cast iron will be small flakes and powder with a dull grey color. If you don't want to use a drill, a coarse file should work too.

Gordy

I'm pretty sure it's cast steel also, my cousin had his welded after a diff bolt broke. His tractor is a lightly used late 90s 4018. This is a less common occurrence with the newer tractors.

Just a random pic I had, cousins hole was bigger with less pieces.

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 8:44 am

by Harry

An easy way to determine the difference between cast steel and cast iron is to grind on it. Watch the spark pattern coming off the grind wheel. Use a piece of steel and cast as a reference to compare. Once you see the difference you’ll never forget.

Harry

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 9:28 am

by Gordy

Harry wrote: ↑Mon Mar 27, 2023 8:44 am

An easy way to determine the difference between cast steel and cast iron is to grind on it. Watch the spark pattern coming off the grind wheel. Use a piece of steel and cast as a reference to compare. Once you see the difference you’ll never forget.

Harry

yep forgot about that

Steel sparks will be bright and longer lived, compared to cast irons duller short lived sparks. But as you said a newbie would need to do both side by side to see for sure the difference

Gordy

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 10:03 am

by MattA

On the old forum bknight187 rebuilt a backhoe axle. I think he swapped the guts from the broken housing to the new housing. I was just the nice guy who passed on the $3500 LBH deal to a local CCI friend who passed it onto Bknight187.

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 10:07 am

by Eugen

MattA wrote: ↑Mon Mar 27, 2023 10:03 am

On the old forum bknight187 rebuilt a backhoe axle. I think he swapped the guts from the broken housing to the new housing. I was just the nice guy who passed on the $3500 LBH deal to a local CCI friend who passed it onto Bknight187.

Here you'll pay $3500 for an LBH if it got squashed by a meteorite! Wow.

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 12:07 pm

by Harry

A few years back I called about a 646 lbh that was all apart, on CL. A few pics of boxes full of miscellaneous parts and the frame with engine rear differential and hoe scattered on a trailer bed. Seller was looking to get 5K for it all. I told him over the phone I would give him 1K sight unseen. He said he wanted to put it together but was relocating to another state and couldn’t take it with him. I asked what was his bottom on the price. He immediately came down to $2500. I replied I don’t know if all the parts are there and would have to buy tires because this GT had been in a fire. He wouldn’t budge on the price. I was tempted to go and take a look but I was still working and my plate was full. It didn’t last but a week and it was gone. If I had purchased it I probably still would not have it done and a money pit for to sure. That’s my Monday ramble.

Harry

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 2:50 pm

by thebuildist

Well..........

I appear to have bought a backhoe attachment. $500 cash. I couldn't pass up a chance like that.

It's a fixer-upper for sure. New hoses for sure, and some rehab to do on the control levers for sure, and a missing tooth, and... whatever else I find along the way. The rod end of the boom lift cylinder seems like it has snapped off and been welded back on at some point. We'll have to see if it was done right. But it doesn't seem to have been beaten to death.

It is a D100, it definitely doesn't have outriggers. But that can be fixed.

The loader didn't have any trouble at all picking it up, even if my rigging did a poor job of keeping it upright.

But it's been raining the last 4 days solid, and the ground is saturated. So I couldn't get enough traction to drive. It's going to have to just sit where it is for a couple days until things dry up.

I even got my golf cart stuck trying to put away the trailer. And that silly golf cart generally has this unexplained SPOOKY good traction. But not today.

So since I already had the tractor out, I just picked up the back end and brought it out of the miry clay, so to speak.

Next I need to get my outriggers designed and get some cylinders ordered for them.

And I need to take a drive to a place about an hour away that has some good deals on steel. He has some 1"x3.5" bar stock that'll be the main structure of the subframe. And he has some 4" wide C channel that'll be the actual structure of the outriggers.

I still need to track down some 3/8 plate or something to build the structure that the outriggers will attach to. I'll see if he has anything I can use. His prices aren't scrap-level cheap. But he's about half what I'll pay retail.

QUESTION: On the factory LBH models, about how many inches of ground clearance at the point underneath the hoe's big vertical pin? I need a starting point to design the subframe....

Bob

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 3:07 pm

by Eugen

Congrats! It'll be a fun project and it'll work out fine. You'll see. FWIW your backhoe is in amazing shape, compared to mine.

E

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 3:24 pm

by MattA

Congrads on the score Bob. I'm sure you'll fab up something nice

Eugen wrote: ↑Mon Mar 27, 2023 10:07 am

MattA wrote: ↑Mon Mar 27, 2023 10:03 am

On the old forum bknight187 rebuilt a backhoe axle. I think he swapped the guts from the broken housing to the new housing. I was just the nice guy who passed on the $3500 LBH deal to a local CCI friend who passed it onto Bknight187.

Here you'll pay $3500 for an LBH if it got squashed by a meteorite! Wow.

Yeah it was a steal 5 years ago even with broken diff bolts and a hole in the axle housing.

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 4:03 pm

by DavidBarkey

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 7:44 pm

by JSinMO

@thebuildist , Congratulations Bob! I’m glad you were able to bring it home. If anyone can get it going it’s you!

Here’s the measurement you asked for. On my 648 the ground clearance of the vertical pin is about 5 inches.

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 8:31 pm

by thebuildist

@JSinMO , thank you very much!

Bob

Re: Case D100 backhoe

Posted: Mon Mar 27, 2023 8:38 pm

by Spike188

https://manuals.ccigt.com/ServiceManual ... -50741.pdf

@Eugen this manual may help you also. It is for the Davis D100

https://manuals.ccigt.com/More/Model-646-646bh-p36.pdf

Sheet 63 Page 110 of this manual is the early undercarage design sheet 65 page 117 for the later D100's

@thebuildist Bob the second manual is for you.

Re: Case D100 backhoe

Posted: Tue Mar 28, 2023 5:52 am

by Toolslinger

JSinMO wrote: ↑Mon Mar 27, 2023 7:44 pm

Here’s the measurement you asked for. On my 648 the ground clearance of the vertical pin is about 5 inches.

If you have the choice, and since you're starting from scratch, you do... You might want to get yourself a little more height on the hoe. Mine will bottom out when I run it on to a 16' tilt trailer. (no gap to run between like a ramp trailer) A PO also added tabs on the support arms on mine, so the hoe sits a couple inches higher than stock to begin with. The loss of max dig depth really doesn't matter, but I can tell you that getting stuck coming on or off a trailer sucks.

Re: Case D100 backhoe

Posted: Tue Mar 28, 2023 6:51 am

by thebuildist

Toolslinger wrote: ↑Tue Mar 28, 2023 5:52 am

JSinMO wrote: ↑Mon Mar 27, 2023 7:44 pm

Here’s the measurement you asked for. On my 648 the ground clearance of the vertical pin is about 5 inches.

If you have the choice, and since you're starting from scratch, you do... You might want to get yourself a little more height on the hoe. Mine will bottom out when I run it on to a 16' tilt trailer. (no gap to run between like a ramp trailer) A PO also added tabs on the support arms on mine, so the hoe sits a couple inches higher than stock to begin with. The loss of max dig depth really doesn't matter, but I can tell you that getting stuck coming on or off a trailer sucks.

Good points. I was concerned there might be an issue with a high center of gravity. From your perspective, moving it up a couple inches wouldn't be a big deal?

Bob

Re: Case D100 backhoe

Posted: Tue Mar 28, 2023 7:50 am

by thebuildist

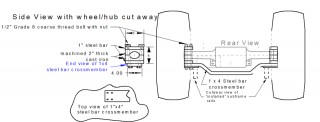

FYI, here are the very beginnings of what I'm thinking for a "quick install" subframe.

The gray is existing tractor structure. The royal blue is the subframe to be built, and the black is the existing backhoe structure.

The subframe rails are made from 1"x3.5" plate. Strong enough to support the all weight and torque of the hoe, all applied right at the fulcrum point directly underneath the rear axle.

when the backhoe is sitting on the ground, the sub frame arms are left tilting up in the air a bit. You back up to the hoe until the square axle housing collars contact the subframe shackles.

Then you install the "capture pin" assembly, hanging from the mid lift arms. (I think. I'm not cetain yet how the capture pin assembly will attach) The capture pin now prevents the front of the subframe arms from lowering down.

Next you hook up hydraulics, and push hoe boom down, which has the effect of lifting the rear shackles up in the air. Because the front arms can't drop down, the subframe comes into its final "parallel-ish" alignment with the tractor frame.

Then you push dipper "out", which has the effect of sliding the subframe forward, until the axle shackles are seated. Then install the 4 big pins to lock the subframe to the tractor frame,

After the 4 pins are installed, install the front boom counterweights and the hoe is ready to use.

I can already see a serious issue with the counterweights, they'll strike the front tires. So I still have to figure that out. Maybe put those weights horizontal on top of the bucket? That will cut your bucket lifting capacity in half. Maybe that's workable for now until I figure something better.

Bob

Re: Case D100 backhoe

Posted: Tue Mar 28, 2023 8:30 am

by Harry

At this point in life I don’t have the energy for a huge project. If there is anyone to tackle this project it’s you Bob. You seem to have a very methodical approach to your projects and this backhoe is no exception. I will be following and inspired by your progress.

Harry

Re: Case D100 backhoe

Posted: Tue Mar 28, 2023 8:36 am

by DavidBarkey

Bob , how much counter weight do you need ?

That being said , if the down riggers were on an angle back wards a few degrees instead of 180 degrees apart then that would help take some of the front rear load off . I am thinking about 15 per side . Then the amount of counter balance would be more for steering . Food for thought . enjoy your breakfast .

Re: Case D100 backhoe

Posted: Tue Mar 28, 2023 9:00 am

by Eugen

But if you somehow keep this tractor on mower duty it'll be the most versatile tractor ever!

Re: Case D100 backhoe

Posted: Tue Mar 28, 2023 9:56 am

by thebuildist

DavidBarkey wrote: ↑Tue Mar 28, 2023 8:36 am

Bob , how much counter weight do you need ?

That being said , if the down riggers were on an angle back wards a few degrees instead of 180 degrees apart then that would help take some of the front rear load off . I am thinking about 15 per side . Then the amount of counter balance would be more for steering . Food for thought . enjoy your breakfast .

I was just musing over that yesterday. I saw that some companies do that, and I didn't see exactly what it accomplished. But you're right, it moves the balance point backward when you're digging, which lessens the need for front counterweight. Very cool!

I'll incorporate that in. The D100 uses that big spur gear arrangement for swinging, which gives it substantially more swing than most modern hoes. I'll just mount the outriggers at whatever backward angle puts them just forward out of striking range from the boom when it's fully swung.

Thanks!

Bob

Re: Case D100 backhoe

Posted: Tue Mar 28, 2023 10:35 am

by thebuildist

I don't see the backhoe bucket teeth in the parts manual.

Anybody know what type/size/nomenclature/brand I'm after? I have two intact teeth and one well-worn tooth mount. I'm guessing I need to replace at least that tooth mount, so I either need to find a set of 3 mounts and teeth, or find one that's very similar in size to what's on there.

Bob

Re: Case D100 backhoe

Posted: Tue Mar 28, 2023 11:54 am

by Spike188

@thebuildist Davis D100 parts are still available through a distributor in Toronto. I have received next day shipment on bushings, pins, and bumpers. I am on service calls the next 2 days and will try to get you the info tonight.

Re: Case D100 backhoe

Posted: Tue Mar 28, 2023 12:12 pm

by Eugen

Spike188 wrote: ↑Tue Mar 28, 2023 11:54 am

@thebuildist Davis D100 parts are still available through a distributor in Toronto. I have received next day shipment on bushings, pins, and bumpers. I am on service calls the next 2 days and will try to get you the info tonight.

Please share this info with myself as well.

Thank you in advance!

Re: Case D100 backhoe

Posted: Tue Mar 28, 2023 12:38 pm

by DavidBarkey

thebuildist wrote: ↑Tue Mar 28, 2023 10:35 am

I don't see the backhoe bucket teeth in the parts manual.

Anybody know what type/size/nomenclature/brand I'm after? I have two intact teeth and one well-worn tooth mount. I'm guessing I need to replace at least that tooth mount, so I either need to find a set of 3 mounts and teeth, or find one that's very similar in size to what's on there.

Bob

Can you build up the mount with weld ??

Re: Case D100 backhoe

Posted: Tue Mar 28, 2023 2:09 pm

by thebuildist

Yes. I did some digging (no pun intended) and it's a crimp on style. Based on its width and angle I think it must be an "H&L" size 2a. So I've ordered one of those from eBay, and that tooth is either going to fit easy or by persuasion. One or the other.

Bob

Re: Case D100 backhoe

Posted: Tue Mar 28, 2023 3:27 pm

by DavidBarkey

thebuildist wrote: ↑Tue Mar 28, 2023 2:09 pm

Yes. I did some digging (no pun intended) and it's a crimp on style. Based on its width and angle I think it must be an "H&L" size 2a. So I've ordered one of those from eBay, and that tooth is either going to fit easy or by persuasion. One or the other.

Bob

Remember , never force it . Get a BIGGER

. And both hands on the handle .

Re: Case D100 backhoe

Posted: Tue Mar 28, 2023 10:21 pm

by thebuildist

the latest design drawings for anyone interested. It shows in a little more detail the concept I'm working on.

I'm hoping to do this work without removing the rear end. You may be curious how I intend to turn the OD of the outer axle tube boss, with it still on the machine.

Simple: I'm going to fabricate a cutter head that bolts to the wheel hub. Remove the wheel, install the cutter, start her up and run the machine to spin the cutter in perfect concentric circles around the OD of that boss. It'll be fiddly, but I think it should work.

The other pure prep that I need to do is modify my 3pt hitch. I built it to accomodate a cylinder that has about 8.5 inches of stroke, which is way more than strictly necessary. But the extra doesn't hurt, except that to make the too-long cylinder fit in place, I had to have the butt end of the cylinder hanging well down below the bottom of the differential housing. And that was fine, but now I need to slide this crossmember through that space as I back up to the hoe assembly. So I need to pull that cylinder off and shorten the housing. I think it'll be easier to cut off the butt end and weld it back on than to cut off and re-machine the threaded gland end. I just wish I knew the original shape of the welded in plug. I'm sure it must slide in/register in the cylinder somehow, and I'd like to just machine off the weld so that I can start with the same clean/square surpfaces that the factory uses. Perhaps I can learn a bit about it on YouTube. But once the cylinder itself is shortened, it's trivial to cut off the rod to size.

Bob

Re: Case D100 backhoe

Posted: Wed Mar 29, 2023 9:37 am

by RoamingGnome

Seems really well thought out Bob. Thanks for sharing the thought process and drawings - can't wait for the progress updates

Re: Case D100 backhoe

Posted: Thu Mar 30, 2023 12:25 pm

by thebuildist

I'm looking in the transaxle service manual to figure out where, exactly, the outer axle shaft bearing is located.

And I think I'm seeing that it only has a bushing. Is that correct, the rear axles are in bushings, not bearings? Do the lbh transaxles have bearings?

Bob

Re: Case D100 backhoe

Posted: Thu Mar 30, 2023 3:09 pm

by thebuildist

Ok, I answered my own question: the LBH models are bushed as well, just with a larger diameter.

I'm surprised that they run so much stress on a bushing instead of a bearing.

I suppose I'll just roll with it.

I am updating my approach, though. The cross member with shackles is too wide to slide between the tires.

So I'll take my 1"x4" steel bar and with it laid flat, use it to build a transverse cross member that clamps permanently around the outer bearing bosses. It'll be welded to the bolt-on collars and hang about 1 1/4 inches below the bottom of the differential. I'm thinking that the 1x4 steel is strong enough to handle the hoe's weight and stresses without meaningful deflection. It'll permanently reduce my overall ground clearance by a couple inches, but I won't have to shorten my 3pt hitch cylinder, and the butt end of that will still be the lowest hanging thing under there.

Then the subframe's rails will hook onto and engage that cross member as they slide into place.

Same basic concept, except that the cross member becomes permanent, and only the rails get removed/installed with the hoe. I will have to do some bracing of the rails to keep then parallel and not twisting, but they were going to need that anyway.

In order to ensure good alignment, I'll have to weld up the entire cross member before I drill out and split the collars, and the collars will have to be line bored. I think I can JUST fit it on my lathe and do the line boring there. If not it'll be a real challenge.

So next I make a trip to pick up the steel, and figure out my contraption to machine the od of the axle housing. And start fabricating a shaft for line boring.

Bob

Re: Case D100 backhoe

Posted: Thu Mar 30, 2023 3:35 pm

by DavidBarkey

thebuildist wrote: ↑Thu Mar 30, 2023 12:25 pm

I'm looking in the transaxle service manual to figure out where, exactly, the outer axle shaft bearing is located.

And I think I'm seeing that it only has a bushing. Is that correct, the rear axles are in bushings, not bearings? Do the lbh transaxles have bearings?

Bob

All 200 and 400 series I have worked on have been Bushings . I would suspect because low speed high weight capacity the loader / BH are as well .

Re: Case D100 backhoe

Posted: Fri Mar 31, 2023 10:42 pm

by thebuildist

Ok, opinion question. Put on your engineering hat and tell me which of these is better:

There will be a 1" x 4" steel crossmember that is "permanently" bolted in place, running under the rear differential, and bolted to collars around the ends of the axle tubes.

The full weight/torque of the hoe will hang from this crossmember when your driving around. The hoe hangs on the crossmember, the crossmember hangs on the outboard wheel bearings and axles, where the load is transferred pretty much straight down to the ground.

The question is about the bolting: The collar going around the axle housings is 2 inches wide, made of cast iron. A set of 4 bolts will run vertically, clamping a big sandwich consisting of, a 1" steel plate on top, then the two collar halves, then another steel plate (needed for spacing) then the 1" thick crossmember itself.

The challenge is that the collar stack is 5" wide, because it has to wrap around the housing, which is 2 9/16 OD. But the transverse crossmember is made of 4" wide bar (I cannot affordably buy any wider). So the collar stack is an inch wider than the crossmember, when looked at from the side. And when you run a pair of bolts on either side of the axle housing, those bolts spread out to around 4 inches wide, too wide to bolt into the 4" steel crossmember.

To mitigate that, I could weld strips on the sides of the crossmember, but I'd rather not. It'll be a real pain to get it flat enough and cleanly enough welded through that I feel confident about its integrity.

There are, however, two different bolting strategies I can persue, bot fairly affordable (around $35) (It's surprising how expensive bigger hi-grade bolts are!)

The first is that I can use 8" grade 8 bolts, drilled at a bit of an angle, so that the bolt heads are closer together than the nuts/washers are. Fot $35, I can get 8 coarse thread bolts, enough to do the whole thing. I'd torque the top nuts to something like 130 ft-lbs, and each bolt is plenty strong, about 17,000 lbs yield apiece. But I have to massage the seat for each bolt and nut so that it's bearing flat against the substrate, and because it's slightly angled, the true vertical clamping force is lessened down to something like 14,000lbs per bolt. Still a whole lot of force.

The second is to use big square-bent U bolts, a pair of them, one facing up, and the other facing down. For $35 I can get a set of 4, 9/16" fine thread, grade 8 ubolts, 3" wide. The 9/16 fine thread bolts have a whopping 23,000lb tensile strength, when torqued to 180 ft-lbs. And they're installed pure vertically, for maximum net force on the "stack". But I'd have to make some kind of insert to accomodate the fact that the "square" bend isn't perfectly square. If I just stick it into drilled holes, the "u" section will stick out, and I need it to seat flat. So I'd have to fiddle with that. And because the holes are too wide for ends of the 4" crossmember, I'd have to add an additional 1/2" or thicker steel plate to kind of act as a keeper/washer, so that the bolt heads aren't just sliding off the outer shoulders of the crossmember.

(you might ask, why don't you use straight Grade8 bolts and nuts and put a keeper plate under the bolt heads. The answer is, you can't affordably buy them any longer than 8 inches, and adding the keeper plate pushes it to more like 9 inches minimum.)

The third option is to run a single set of 5/8" fine thread grade 8 u bolts on each side. basically the same photo as above, but instead of having an inboard and outboard set of u bolts, there would just be a single ubolt on each side, I think located off-center inwardly, because the torque is trying to peel away the inner side of the joint more than the outer. About 26,000lbs tensile strength.

About the same overall cost, less complexity to drill/install, and the parts not as tightly crammed in there as the other two solutions. It seems a little more elegant overall. If I could afford 3/4" ubolts like this, I'd do that for sure. But that cost jumps up to around $100, and I don't think the extra $65 is necessary.

So I guess I'm leaning towards the U bolts, and the 9/16" U bolts in particular. When I imagine all the scenarios, the U bolts seem more stout, more secure, and I think 4 9/16 bolts must have an edge on 2 5/8" bolts.

But I'd love to get you folks' opinions, especially if anyone sees something that I've missed.

Bob

Re: Case D100 backhoe

Posted: Sat Apr 01, 2023 12:07 am

by Spike188

Bob, you have my full attention. I am just trying to figure out how using your idea and machine constraints and how I might do it. Because there is a 646 here in the bone pile that is broken in half and came with a bent under carriage, your putting time and thought into the build is a good idea. I will sleep on this tonight and maybe wakeup with an idea, not.... But I did get out the Macmaster Carr catalogue.

Re: Case D100 backhoe

Posted: Sat Apr 01, 2023 7:15 am

by DavidBarkey

@thebuildist Bob I am a firm beleaver that overkill is underrated . But I think you are taking it up a notch . I assume you are using cast iron blocks for easy machining , I would use leaded steel . The 1x4 is a good idea because it is on it flat . But I would also put tabs on to pick up the mounts for the sleeve hitch to tie the diff. together . As for the mounting blocks at the tube ends I would go with 1/2" plate on top and truck axle U bolts . But on the bottom have the 1x4 directly under the iron block with a 1/2" clamping plate . The only real load will be on that point when driving around . The outriggers will take the majority of the load when down . There are back hoes bigger than that one that hang off nothing but the 3pnt. hitch . example .

I have worked on larger tractors with bigger back hoes and the frames are held in pace with 1/2' u bolts and 1/2 plate with no issues . Look at some of the back hoes in that size range and what the different manufacture are using for the sub frame and to mount it . You will be surprised . Then just up it a bit for piece of mind . Thats what I do because I know the engineers cheat the lower limits . The bigger and heavier you make everything is going to further add weight stress on the machine . As for front weight , do you have room in front of the axle down low . I am thinking a weight that would slide into a receiver hitch welded to the front of the subframe . You could use the loader to help lift it into place and then lock in place with a pin . I hope this helps more than muddy the waters for you . You smart guy , you will figure it out . I Am sure of that .

Re: Case D100 backhoe

Posted: Sat Apr 01, 2023 11:04 am

by thebuildist

Thanks, @DavidBarkey that's all good advice.

I do plan to tie the center of the crossmember to the transaxle, as you mention. I just mentally want to be sure that I'm not asking the transaxle to carry any weight/shock load.

I agree that leaded steel would be the best choice for the collar, but I have cast iron in hand, and I think it's good enough.

I'm surprised that the steel cap and bottom plate could be 1/2" instead of 1", but now that I think about what you said about larger backhoes, I guess you're right. So 1/2" it is.

Do I understand you to say that a single 9/16" ubolt would be fine? I could imagine that. Would you guess 9/16, or do the 5/8" for that "overkill"?

The only tricky part that I anticipate is that I'm going to have to shim between the collar halves: I'll machine the collar in a single piece, then bandsaw it in half. But if I don't shim between the halves, I think that U-bolt may actually crush/deform the axle housing. So I'll need to shim it enough for it to be snug, but not so tight that it crushes. And that makes it all the more important that the crossmember be tied to the differential in the center, to be sure that it never rotates forward or backward out of the desired flat position.

To bend the 1x4 steel bar I intend to heat it up with a rosebud and put it in my electrified 20 ton press. It's going to be a challenge to get the bends just right, both for their location and their degree. In the past my guesses/horse sense for where and how much to bend haven't been terribly accurate. And once you've put a bend in, it's very difficult to take it back out and start over, so I'm going to try to do some youtube research for tips and draw up a specific bending plan with dimensions, to where I can work to a specified measurement and hopefully get it very close to perfect on the first attempt.

Bob

Re: Case D100 backhoe

Posted: Sat Apr 01, 2023 12:15 pm

by Spike188

This is a warning found in a Case backhoe manual but I have not been able to locate which one it came from. The point is that the Case under carriage design did not address flex of the frame from stresses applied to the loader tower mounts and the backhoe. Dave has a good point in that the rear axil stress as Case designed was only during transport. Using u bolts or clamping systems from trailer axils seems like a good alternative or source for mounting options.

The previous owner of my 646 backhoe ran the differential so low on oil that the axil eat through the outer bushings, and wore into the casing about 0.100". The stress on the bull gear was enough to break the axil spline off of the bull gear. My thought is that if proper periodic changes of oil and maintaining oil levels the bushings would not have degraded to the point of complete failure.

Re: Case D100 backhoe

Posted: Sat Apr 01, 2023 12:42 pm

by DavidBarkey

Do I understand you to say that a single 9/16" ubolt would be fine? I could imagine that. Would you guess 9/16, or do the 5/8" for that "overkill"?

Me I would go for 2 - 1/2 u bolt on each side .

The only tricky part that I anticipate is that I'm going to have to shim between the collar halves:

Me , I would rough machine to with in width of cut . Then cut in half put haves back together and finish machine to about .010" undersized . Mark halves so alignment and pairs can be identified .

Re: Case D100 backhoe

Posted: Sat Apr 01, 2023 2:40 pm

by Eugen

Here's a pic of the big Case 680 transaxle and how it's bolted to the frame. The 4 bolts are 5/8. The backhoe on this is massive. Only the bucket weighs as much as the D100 most likely.

If I were you I'd consider securing the cross member to the transaxle in more points such as the sleeve hitch attachment screw holes, and possibly the two top bolts where the 3pth connects.

Re: Case D100 backhoe

Posted: Sat Apr 01, 2023 7:55 pm

by thebuildist

You see that? THAT is why it's so nice to have this forum with smart people. OF COURSE I should rough-machine, then split it, then final machine it. Great point.

Bob

Re: Case D100 backhoe

Posted: Sat Apr 01, 2023 8:05 pm

by Eugen

I would be worried that the cast iron will snap when tightened. I think that a sandwich of plates, even welded together to get the thickness you want is better. I also think that 0.010 is too little to provide enough clamping strength.

Re: Case D100 backhoe

Posted: Sat Apr 01, 2023 8:15 pm

by thebuildist

So I'm hearing this group say that the u bolts are the way to go.

Check.

1/2" u bolts are not an option, for this reason: off the shelf they don't make 1/2" bolts in the "2 9/16"/"2 5/8" spacing that I need. You can get them custom made, but those are more like $100 for 4 of them.

So I could do the two 9/16 like I mentioned. But at this point I'm inclined to just do single 5/8 u-bolts on each side. I'm a little concerned that doing two sets of 9/16" holes in each set of collars might actually weaken them a bit. Balancing that against a single 5/8 hole, and believing that the single 5/8 bolt is more than strong enough, makes me inclined to just install a single 5/8 u bolt on each side.

And attach the center of the crossmember to the differential in the center. (probably I'll weld a tab or two to the 3pt hitch backing plate, which is well-attached to the differential)

And do the final machining after the split has been done.

As of now, unless I hear good arguments otherwise, that's my plan.

And thanks, everyone!

Bob

Re: Case D100 backhoe

Posted: Sat Apr 01, 2023 8:34 pm

by thebuildist

Eugen wrote: ↑Sat Apr 01, 2023 8:05 pm

I would be worried that the cast iron will snap when tightened. I think that a sandwich of plates, even welded together to get the thickness you want is better. I also think that 0.010 is too little to provide enough clamping strength.

By .010 being too little, do you mean that I should machine the collar to more than .010 undersize? You think I chould machine it .015 or 020 undersize?

Like you, I am concerned about the cast iron under that kind of clamping force after I've cut away 20% of it by drilling two big holes in it. But cast iron is pretty darn strong in compression. So I think that if I limit myself to one 5/8" hole, that it'll hold.

And I can't wrap my head around how to weld the stacked plates together. All I can do is weld them around their outer perimeter. And where the collar contacts the axle housing I think it needs to be seamless/solid.

Is there a way to think about it that I'm missing?

Bob

Re: Case D100 backhoe

Posted: Sat Apr 01, 2023 9:20 pm

by JSinMO

@thebuildist Sounds like you have kinks pretty well worked out.

not sure if this will be helpful but I took a couple of photos of the mounting plate on the back of my 648. My subframe bolts to the center of the rear end.

Looks like your planning is well past this point but I thought it couldn’t hurt to have a look!

Re: Case D100 backhoe

Posted: Sat Apr 01, 2023 9:57 pm

by thebuildist

Thanks, @JSinMO !

I really appreciate all the info I can get!

Bob

Re: Case D100 backhoe

Posted: Sun Apr 02, 2023 9:06 am

by Eugen

thebuildist wrote: ↑Sat Apr 01, 2023 8:34 pm

By .010 being too little, do you mean that I should machine the collar to more than .010 undersize? You think I chould machine it .015 or 020 undersize?

Not the machining of the bore, sorry. I meant the distance between the two halves once you put them on the axle.

Like you, I am concerned about the cast iron under that kind of clamping force after I've cut away 20% of it by drilling two big holes in it. But cast iron is pretty darn strong in compression. So I think that if I limit myself to one 5/8" hole, that it'll hold.

And I can't wrap my head around how to weld the stacked plates together. All I can do is weld them around their outer perimeter. And where the collar contacts the axle housing I think it needs to be seamless/solid.

Is there a way to think about it that I'm missing?

Bob

I'm in a hurry to leave home now but I'll come back with a drawing.

Re: Case D100 backhoe

Posted: Sun Apr 02, 2023 11:53 am

by Eugen

Re: Case D100 backhoe

Posted: Sun Apr 02, 2023 3:31 pm

by thebuildist

I do have to admit that I hadn't thought about it that way.

I'm going to have to think about it for a little bit. The hole in the middle needs to be about two and 9/16. And the steel that I am working with is 4 in high. So if I split a single piece of steel down the middle into upper and lower collars, then the thickness at the very top and very bottom of the colors will be just a smidgen over a half inch. The cast iron I have is just a big 2-in thick plate. So I can kind of cut out whatever shape I want out of that. And I was going to have the collar be a minimum of 1 in thick all the way around.

So my choices are to go with cast iron with a full 1-in thickness around the whole perimeter.

Or use the steel plate with a single joint in the center line of the collar thickness. I can see how that single vertical joint running front to back shouldn't present any terribly big problems strengthwise. It might be a bit of a challenge to drill the holes for the u-bolt because they'll be going right down that seam line. But I could probably figure it out.

And if I do use the steel plate I can either consume 20 inches of the 1x4 bar, two pieces of bar for each side, and have half inch thickness at the top and bottom.

Or I can consume 40 inches of the 1x4 bar, four pieces of bar for each side, and have for 1 in thickness at the top and bottom.

I'm trying to get away with just buying a single 12-ft stick of the 1x4 bar. It's $200 per stick and I'd hope to just buy one of them. But if I do have to buy a second one it's not like I'd have no use for it.

And I don't really know where I'll be getting half inch bar. I'm getting the 1-in bar for about what you normally pay for half. So maybe I'd be best off not using half anywhere and just buy two sticks of 1 in and use it for the whole project.

I'm going to have to think about this.

Re: Case D100 backhoe

Posted: Sun Apr 02, 2023 3:53 pm

by Eugen

Another piece of bar top and bottom can be welded to make it thicker.

More to think about. Also, consider what is $50-$100 extra for something you want to use many years.

Re: Case D100 backhoe

Posted: Sun Apr 02, 2023 7:38 pm

by Harry

Bob, you mentioned cast iron. I would think cast iron would be harder to work with than steel.

Harry

Re: Case D100 backhoe

Posted: Tue Apr 04, 2023 2:23 pm

by thebuildist

I find myself in the uncomfortable, unprecedented position of having paid money, good money, for steel/materials.

But for what I need, you're not going to find it just laying around. And I got it for less than half of retail.

So I'm sad but happy. Total backhoe project investment just surpassed $1200. It better work....

Bob

Re: Case D100 backhoe

Posted: Tue Apr 04, 2023 4:34 pm

by Harry

I pick up scrap metal and sometimes buy it if I can get it cheap enough. So after doing that for a good thirty years I have acquired a lot of metal to use for projects. Bob I thought of you when the farmer I purchased the combine weights was selling 1”x3”x20’ bar stock for .15 a pound.I passed on it myself. Just think that this attachment will be one of a kind that you built with your own brains and hands. Your conviction and persistence should be commended.

Harry

Re: Case D100 backhoe

Posted: Tue Apr 04, 2023 4:43 pm

by Eugen

thebuildist wrote: ↑Tue Apr 04, 2023 2:23 pm

I find myself in the uncomfortable, unprecedented position of having paid money, good money, for steel/materials.

But for what I need, you're not going to find it just laying around. And I got it for less than half of retail.

So I'm sad but happy. Total backhoe project investment just surpassed $1200. It better work....

Bob

On the plus side, you are building a tool for your family, to use many years. It's as healthy as it gets Bob. I can think of many unhealthy ways to burn $1000.

Sometimes we get an amazing deal, other times we pay half price or even full price. Such is life. Do the best you can with what you got and enjoy the process.

Re: Case D100 backhoe

Posted: Tue Apr 04, 2023 5:17 pm

by thebuildist

Thank you, both of you, for your encouragement.

Assuming it all works like I imagine, I'll be thrilled with it. But if I've misjudged something, then it'll be a costly mistake.

I'm just not used to having such high stakes. I usually work with "free" and "cheap" and there's no big penalty for failure.

But I'm going to "man-up" and GIT ER DONE.

LOL

:-)

Bob

Re: Case D100 backhoe

Posted: Tue Apr 04, 2023 7:42 pm

by JSinMO

@thebuildist. Here’s another way to think about it Bob. Let’s say it doesn’t work for some odd reason, even though that is highly unlikely! But if it didn’t work out you would still have a ready for service backhoe that I would think would be quite marketable. I’d venture to guess at $1200 you’re still below a sale price for a piece of equipment that has been gone through and ready to mount to some one else’s tractor. I feel the same way about the old truck I’m working on. I’ve put some into it but I know I’m still below market value at this point.

At least that’s what I tell myself!

Re: Case D100 backhoe

Posted: Thu Apr 06, 2023 3:05 pm

by Merchlewitz

Is the D100 the only backhoe that fits a 648? Would a D130 work or a Case 32 backhoe?

Re: Case D100 backhoe

Posted: Thu Apr 06, 2023 3:24 pm

by Eugen

Merchlewitz wrote: ↑Thu Apr 06, 2023 3:05 pm

Is the D100 the only backhoe that fits a 648? Would a D130 work or a Case 32 backhoe?

Even the D100 is almost too big. The Case 32 is waaay too big. Even big tractors take a big hit on the frame with backhoe attachments when they start digging. I even have doubts the 648 can carry a model 32 backhoe. Just my opinion.

P.S. Welcome to the forum! Hope you enjoy it here!

Re: Case D100 backhoe

Posted: Thu Apr 06, 2023 3:27 pm

by thebuildist

In my opinion, which admittedly is not as experienced as others who may weigh in, I cannot imagine hanging a d130 off of the 648. I think it's way too big.

And I don't really know what a case 32 is. So you could judge my opinion based on the size of the d130.

For what it's worth.

Bob

Re: Case D100 backhoe

Posted: Thu Apr 06, 2023 4:10 pm

by RoamingGnome

A Case 32 is a "Full Size" backhoe attachment - it's what's hanging off the back of my '65 Case 530 CK - Construction King

Re: Case D100 backhoe

Posted: Thu Apr 06, 2023 5:15 pm

by DavidBarkey

@Merchlewitz Welcome to the site . Hope you enjoy you time here .

Re: Case D100 backhoe

Posted: Thu Apr 06, 2023 9:17 pm

by Merchlewitz

RoamingGnome wrote: ↑Thu Apr 06, 2023 4:10 pm

A Case 32 is a "Full Size" backhoe attachment - it's what's hanging off the back of my '65 Case 530 CK - Construction King

Ahh good to know, I couldn’t tell size by pictures..

Re: Case D100 backhoe

Posted: Thu Apr 06, 2023 9:17 pm

by Merchlewitz

DavidBarkey wrote: ↑Thu Apr 06, 2023 5:15 pm

@Merchlewitz Welcome to the site . Hope you enjoy you time here .

Thanks!

Re: Case D100 backhoe

Posted: Thu Apr 06, 2023 11:45 pm

by Timj

Merchlewitz wrote: ↑Thu Apr 06, 2023 9:17 pm

DavidBarkey wrote: ↑Thu Apr 06, 2023 5:15 pm

@Merchlewitz Welcome to the site . Hope you enjoy you time here .

Thanks!

D100 for sale in southern WI

https://www.facebook.com/marketplace/it ... tid=dXMIcH

Re: Case D100 backhoe

Posted: Fri Apr 07, 2023 12:12 am

by Merchlewitz

I asked about this… it says d130 on it.. The guy said it’s far too big for a compact tractor?

Re: Case D100 backhoe

Posted: Fri Apr 07, 2023 7:53 am

by Timj

Merchlewitz wrote: ↑Fri Apr 07, 2023 12:12 am

I asked about this… it says d130 on it.. The guy said it’s far too big for a compact tractor?

Opps, sorry I didn't look close enough, thought it was a 100.

I'll keep an eye out, it seems like there's always a d100 for sale. I'm looking for a mini excavator so the small backhoes come up when searching.

Re: Case D100 backhoe

Posted: Fri Apr 07, 2023 8:10 am

by Merchlewitz

Timj wrote: ↑Fri Apr 07, 2023 7:53 am

Merchlewitz wrote: ↑Fri Apr 07, 2023 12:12 am

I asked about this… it says d130 on it.. The guy said it’s far too big for a compact tractor?

Opps, sorry I didn't look close enough, thought it was a 100.

I'll keep an eye out, it seems like there's always a d100 for sale. I'm looking for a mini excavator so the small backhoes come up when searching.

I appreciate any help I can get!

Re: Case D100 backhoe

Posted: Fri Apr 07, 2023 10:09 am

by thebuildist

So I stumbled across this sign, and for the first time, it'll soon be true for me!

How cool is that?

LOL

https://www.amazon.com/dp/B07V1TMRP8

Bob

Re: Case D100 backhoe

Posted: Fri Apr 07, 2023 10:38 am

by Eugen

hahahaha, it does not really apply to us here in Canada, but I like it

Re: Case D100 backhoe

Posted: Fri Apr 07, 2023 11:38 pm

by JSinMO

I might have to get that! I have the perfect spot for it in the shop!

Re: Case D100 backhoe

Posted: Sat Apr 08, 2023 7:14 am

by thebuildist

Re: Case D100 backhoe

Posted: Sat Apr 08, 2023 8:47 am

by DavidBarkey

Re: Case D100 backhoe

Posted: Sat Apr 08, 2023 10:05 am

by Eugen

They gonna take away my backhoe FROM MY COLD, DEAD HANDS!

Re: Case D100 backhoe

Posted: Sat Apr 08, 2023 10:24 am

by RoamingGnome

Re: Case D100 backhoe

Posted: Mon Apr 10, 2023 1:02 pm

by Gordy

I was looking at signs similar to that. My buddy who can be quite paranoid at times, said NO. If you had to put down a criminal and the cops saw those signs, even a crappy lawyer would use them to show prior intent on your part. Just the world we live in today

Gordy

Re: Case D100 backhoe

Posted: Tue May 16, 2023 1:13 pm

by thebuildist

Just an update on the backhoe project:

Step 1 is complete, I have the new tires installed.

Step 2 is to machine the outer axle bosses to receive the heavy clamps I'll put on them, from which the weight of the hoe will hang.

The bosses need to be machined perfectly round in order to eliminate any egg-shapedness or high spots. I need that 1100 lbs or whatever to hang on a smooth, clean journal on the boss, which will transfer that load straight through to the cleanl, smooth journal on the outer axle shaft. The axle tube is made of cast iron, and it'll crack if it's forced to flex. So that means no wiggling/jiggling of the clamp is allowed, and no point-pressure is allowed between the inner bore of the clamp and the outer bore of the boss. So I can't leave the irregularly shaped/lumpy cast surface.

To that end, I've built a jig to bolt to the wheel hub that contains a quill that can slide in and out. And I've machined the end of that quill with a femal R8 taper into which you can mount a small boring head that I use with my mill.

The quill sliding inward/outward moves the cutter across the horizontal length of the journal, and the adjusting the boring head cranks the cutter inward to increase cutting depth. A piece of 3/8" allthread acts as a driving screw. The driving screw engages a nut attached to the end of the quill, and turning the driver screw causes the quill to slide inward or outward.

In practice, I'm running the tractor and driving the wheel hub backward. While it spins, I grab the handle on the driver screw and hold it still, and that pulls the quill outward, across the length of the journal. Once it reaches the outer edge I stop the wheel hub, and use a drill to drive the quill back in, resetting it for another pass. I dial in the boring head about .040" deeper, and then proceed with another pass.

The quill itself is made up of some heavy 2" dom tubing that I picked up from the steel guy the other day. One of the trickiest things is getting the quilll adjusted to be parallel to the axis of rotation, so that you cut a cylinder and not a cone. To that end, the quill is suspended between a pair (inner and outer) of 3-point support halos. Each 3 pt. support halo is like a steady rest on a lathe, where it touches the od of the quill at 3 evenly spaced points. Each point of contact can be adjusted inward or outward. So by adjusting the position of the quill inside the inner or outer support halo, you can adjust the quill left/right and up/down.

So the process of getting the quill adjusted to travel true to the axis is very finicky. The passenger side is the easiest to work on, because there's no travel motor to contend with, which leaves plenty of room to work. So I'm doing the whole adjustment process on that side, and once I have it dialled in to run true, I'll transfer over and do the driver's side.

And I'm having to tweak the details and design of the tool itself as I go, figuring out that "that hole needs more clearance" and "that thing there is hitting that other thing there when I dial it all the way out." Etc.

So at this point I've done about 20 passes, and the outer end of the journal, which started out being .100 larger than the inner end, is down to about .030" thicker. So I'm getting closer. But my 3/8" allthread driver screw just stripped out, so I made up a new 3/8 driver screw and replaced the driven nut with a 1 inch long threaded sleeve. The long sleeve should engage many more threads, and ought to hold up to wear a little better.

But my quill has become very hard to slide, and I haven't yet figured out why. Both my 3-pt halos aren't super snug. So I think the quill is rubbing on the housing itself somehow. So before I reassemble, I'll pull the quill all the way out and see if it has galling/wear that I can see. And address whatever is binding.

Meanwhile, the boss itself is way off center. Not even close. The extra thickness on the front side of the boss has now been completely cut away, while the back side of the boss hasn't even cleaned up for roundness yet. As soon as I have machined out the cone-shapedness, I'll just stop there. The top surface is the real key, that'll hold all the weight. I think it'll be 100% cleaned up on top, in front, and underneath. There will just be a few pockets at the very rear edge. The big new clamp, once it is bolted on, being machined to within .005" or so, will restore full strength and rigidity to the axle housing/boss. But until then, the housing is weaker than it used to be.

I'm considering attaching the clamp to the axle tube permanently, using JB Weld to fill any gaps between the axle tube and the clamp.

I'd love to hear people's opinions about using JB weld.

Bob

Re: Case D100 backhoe

Posted: Tue May 16, 2023 6:11 pm

by Harry

Nice ramble Bob. Always a pleasure to read your posts.

Harry

Re: Case D100 backhoe

Posted: Tue May 16, 2023 6:38 pm

by Eugen

I am confused about what you are trying to do Bob.

Re: Case D100 backhoe

Posted: Tue May 16, 2023 7:30 pm

by Spike188

Bob, Reading through your post, visions of JB weld kept popping into my mind. This is a perfect application for it. Make a paste and apply to the axle housing, then before the paste is set, clamp the brackets down and torque. I have a lot of experience with using this method for shaft rebuilds.

Re: Case D100 backhoe

Posted: Tue Dec 26, 2023 11:20 pm

by thebuildist

So... I haven't made any progress since June. It's getting where I don't really recall the full details of precisely what I planned to do. It's not that I think I can't do it. It's that I haven't yet gotten real clarity/comfort on precisely what to do next.

So I'm thinking about admitting a measure of defeat, and going a different route, namely the "towable backhoe" route.

There's nothing preventing me from coming back later and doing it the original way. But this way would be way faster to accomplish, and I think I could dig right in. So to speak.

I just need to

1. mount the backhoe onto a towable axle. Easy to do.

2. procure/install essentially the same hydro lines I would have used before, to power the hoe from the tractor's hydraulic system. Easy to do, just plug the lines into the same quick-disconnects that the loader runs off of now.

3. replace some/all of the hoe's hoses, and get the control valve cleaned up and working, etc. I have to do that anyway.

and

4. make a way to mount the backhoe to the tractor's 3-pt hitch. Not to drive around with it, it's way too big for that, but a way to stabilize the hitch end of the hoe so that when you push or pull on the boom, the hitch end can't just jump and flex and move all around. Kind of a way for the hoe to use the tractor as a counterweight to push and pull against.

i built the 3point pretty rugged, but this will be asking a lot of it. Especially the top link. I think the top link mount is the weakest link, no pun intended. But I don't see an easy way to reinforce the top link very much. It's mounted to the 3pt backplate, which is mounted to the transaxle. So the top link is basically attempting to rotate the transaxle forward and back. And I'm given to understand that that's a bit of a weak link on these machines.

That was one benefit of my planned under-axle mounting plan, was the heavy 1 inch steel mount plate would be bolted to the transaxle, and serve to tie together and reinforce the entire back end.

I suppose I might forego the 3 point approach and instead go with a really long trailer tongue? So that by the time the force of movement reaches the tractor hitch, it's at the end of a long lever, and it takes relatively little tractor "effort" to make the hitch end hold still? I'd have to build the tonge pretty beefy, but that's not too hard.

Any thoughts or advice about this approach?

Bob

Re: Case D100 backhoe

Posted: Tue Dec 26, 2023 11:28 pm

by RoamingGnome

Bob - up here in the great white north our version of Harbor freight (Princess Auto) sells a towable excavator that sounds very much like what you're describing - here's a link to a YouTube video of it in action

https://youtu.be/4zPn9E6hit4?si=QSvymIVM6TftfbbJ

The actual listing is here -

https://www.princessauto.com/270cc-tow ... 008936726

You could make the stabilizer legs swing together, under the excavator part and use them for a tongue to tow it with - kinda like the split tail of a towable piece of artillery...

Re: Case D100 backhoe

Posted: Wed Dec 27, 2023 9:48 am

by JSinMO

RoamingGnome wrote: ↑Tue Dec 26, 2023 11:28 pm

You could make the stabilizer legs swing together, under the excavator part and use them for a tongue to tow it with - kinda like the split tail of a towable piece of artillery...

That’s a pretty good idea, and I think it would be an interesting build.

What about hitching the backhoe to the tractor with a 3 point hitch bar and a bolts instead of a hitch pin.

- IMG_4429.jpeg (38.55 KiB) Viewed 3270 times

That would give you the benefit of using the heavier lift arms and the weight of the tractor as a counterweight with out needing to change how it’s attached once the hoe is in position to dig. And add stabilizers to the tractor end of the hoe. So you would have stabilizers at each corner of the hoe.

I’m just spitballing here! But maybe there’s a usable idea in there somewhere!

Re: Case D100 backhoe

Posted: Wed Dec 27, 2023 10:29 am

by thebuildist

great minds think alike? Because I'm thinking along similar lines with the 3pt hitch bar.

Looking at towable backhoes on youtube, most of them set up for a 4-point stance for digging: the two outriggers at the hoe end and some kind of fixed resting pads at the hitch end.

So I'm thinking of that approach: build the precise same outriggers that I've already drawn up (and bought cylinders for)

And then build a pair of resting pads up at the hitch end. Maybe even including a ground engaging spike, to help the pad hold still. And maybe add 300 or so pounds of weight at the tongue, enough to almost balance the hoe end.

But then tow the thing using only the 3 pt arms, not the toplink. Have a 3pt hitch bar that can lift up on or push down on the hitch end of the hoe/trailer, but swiveling so the trailer can turn. So lift up the 3pt arms to drive around. Then downpressure the 3pt arms to begin digging. (I built my 3pt with downpressure.) The fixed weight at the hitch end plut putting the tractor's weight on it should really anchor it in place and allow the hoe to dig/lift harder than most lightweight towable backhoes can do.

The only thing I'm having doubts about is how much of a pain it'll be when you want to move up the trench line. You'll have to raise the outriggers, get off the hoe, get in the tractor seat, lift the 3pt, drive forward, put the 3pt back down, and go get back in the hoe seat, drop the outriggers, and then dig.

Certainly less convenient than having the hoe right on the tractor. But probably not a disaster? And should have similar digging performance to the tractor-mounted type?

Bob

Re: Case D100 backhoe

Posted: Wed Dec 27, 2023 11:03 am

by Harry

I’ve never seen a towable in use like the ones you guys have mentioned. I have used my 644 lbh a lot this past summer and can only comment on it’s performance. I works well and the hoe is very powerful. Maybe sometimes to powerful. With the GT in the air on the rear stabilizers and the bucket in front with the open end down in the dirt. The hoe will still pull the whole GT towards the hole your trying to dig. So after using it in the same area digging away the GT will stop moving because the stabilizers have been pulled into the ground a few inches and the cutting edge of the bucket also. By now the GT needs to be moved to dig more. With a heavier excavator they probably don’t get pulled by the hoe, especially a tracked one. I also believe a four digit GT with a hoe the rear stabilizers move out away from the GT instead of straight down like the three digit. This would give it more stability when digging. Just some food for thought

. That’s my ramble for this morning guys.

Harry

Re: Case D100 backhoe

Posted: Wed Dec 27, 2023 11:57 am

by JSinMO

Harry wrote: ↑Wed Dec 27, 2023 11:03 am

I’ve never seen a towable in use like the ones you guys have mentioned. I have used my 644 lbh a lot this past summer and can only comment on it’s performance. I works well and the hoe is very powerful. Maybe sometimes to powerful. With the GT in the air on the rear stabilizers and the bucket in front with the open end down in the dirt. The hoe will still pull the whole GT towards the hole your trying to dig. So after using it in the same area digging away the GT will stop moving because the stabilizers have been pulled into the ground a few inches and the cutting edge of the bucket also. By now the GT needs to be moved to dig more. With a heavier excavator they probably don’t get pulled by the hoe, especially a tracked one. I also believe a four digit GT with a hoe the rear stabilizers move out away from the GT instead of straight down like the three digit. This would give it more stability when digging. Just some food for thought

. That’s my ramble for this morning guys.

Harry

Good ramble Harry. You have a lot more practical experience than I do but in my limited time working the backhoe I have the same experience. It was surprising to me that even with the engine at idle the hoe can easily drag the tractor around. So finding a good way to anchor it is a big part of this. Mine also has stabilizers that move straight down. I also believe outriggers would be much better.

In this scenario I don’t think you’ll need to worry about using the top link Bob. It’s not really doing anything to help.

As far as moving and resetting as you dig it’s pretty much the same procedure if the hoe is mounted to the tractor so I don’t think you’re really at any disadvantage there. I’d b more concerned with finding a good way to pin it to the ground.

Re: Case D100 backhoe

Posted: Wed Dec 27, 2023 1:39 pm

by thebuildist

Good and helpful observations from you both.

I'll be sure to incorporate some kind of ground-engaging cleats on all four ground pads. Maybe I can get clever like Case did and make flippable outrigger feet, one side with cleats the other with a smooth pad.

The other direction I'm thinking is that for the structure of the tongue I think I'll intentionally build it much heavier than I otherwise would. I have from an old project about 400lbs of steel bars that are 48" long, 1/2" thick, and 1 1/2" wide. A while back, to build a front weight attachment I welded them into stacks of about 8, creating laminated steel bars that are about 4" x 1.5" x 48". Each laminated bar weighs about 80 lbs if I recall. I think I'll build the trailer tongue out of a couple of those laminated bars. And I'll sling the rest of them right underneath the front hitch to act as the crossmember for the front ground pads. I'll be silly strong, and I need the weight to counterbalance the hoe's working forces. And it uses up materials that I don't otherwise need anymore.

The only trick is that this hoe trailer will outweigh the tractor itself. So I need to be careful on the hills around here.

Bob

Re: Case D100 backhoe

Posted: Wed Dec 27, 2023 2:33 pm

by RoamingGnome

(ramble warning

) It will be interesting to see the progress of this new direction for your build. There have been lots of good comments made here and the wide variety of YouTube videos let's you see what others have done. From my experience with excavators big and small - I think the biggest force when digging is going to be the bucket and load trying to pull the thing over forwards on its nose. Good long outriggers set as far forward as possible would counteract that shift in center of gravity when there is a load in the bucket. After the stabilizers are set out front extra counterweight on the trailer tongue should add to the stability. Mini excavators have that blade out front more for stability than for backfilling trenches - although that's a handy secondary use....