Page 5 of 26

Re: Case 644 loader repairs

Posted: Tue Nov 15, 2022 9:45 am

by Eugen

JSinMO wrote: ↑Mon Nov 14, 2022 7:37 pm

All I can say is don’t fight your OCD! If you do it will drive you crazy every time you look at the tractor. Maybe a step back and reevaluate? Possibly another better suited engine could be had? You always come up with good solutions, so no worries!

Haha, thanks Jeff. I don't have clinical OCD, it's more that feeling you get when you fit a square peg in a round hole. It'll go in and even work, but as you say, will make you shake your head "what was I thinking" every time you look at your tractor. I think everyone has their own personal threshold for things less than perfect. I have a pretty large tolerance for departures from perfection/OEM and this particular engine fit just went too far.

I wanted to sleep on it for a bit and see if anything changes in how I feel about it. It's getting clearer that the K321 from the 244 goes to the bigger brother 644.

Re: Case 644 loader repairs

Posted: Fri Nov 25, 2022 1:27 am

by Eugen

Done some work tonight towards the k321 going in, but too tired to take pictures. Have three hydraulic pumps. One with 1/2" shaft but modified inlet by the PO. Another with the 9/16" shaft. Another that was disassembled by me a while ago, also with 1/2" shaft. As my Lovejoy coupler was 1/2 inch I decided to go with the disassembled one. Cleaned it up well in diesel and then brake cleaner and bowed dry all parts. Oiled and put together. There were some signs of wear on the side plates, but cannot say if it was medium or light wear. We'll see how it does later on the tractor. Then I installed it on the engine together with the pump adapter. Taking a bit of a risk going with this engine for the 644, as I go by the word of the guy who sold it to me, who said the engine works.

Re: Case 644 loader repairs

Posted: Sat Nov 26, 2022 7:24 pm

by Eugen

Thank you

@Timj ! No other way could I tighten the hard line from the pump to the tcv, on the tcv side.

Re: Case 644 loader repairs

Posted: Sun Nov 27, 2022 12:05 am

by Eugen

Using parts from other tractors because this one came with them missing. For instance the posts that hold the hydraulic cooler and tank.

The pump now fits the original hard line too.

Re: Case 644 loader repairs

Posted: Sun Nov 27, 2022 11:53 am

by Jancoe

While your in there putting this machine together I'd be tempted to swap some better parts off your running loader. Especially if your steering gears, steering arm and well anything really. Would save you from some future expenses and not being able to source those parts. I have a second 6018 that was running and working until I had to steal the steering cylinder off it to put on my 6018bh while I was working it digging stumps and the seals let go. Then I was rebuilding the front axle on the bh and found some very worn spindles at the axle ends so now the 6018 doesn't have a front end underneath right now. But my bh has a nice and tight front end. I've since rebuilt the steering cylinder and have swapped them back. This winter I'll be dragging the 6018l back in for repairs. Just a thought.

Sent from my SM-S906U using Tapatalk

Re: Case 644 loader repairs

Posted: Sun Nov 27, 2022 9:00 pm

by Eugen

Jancoe wrote: ↑Sun Nov 27, 2022 11:53 am

While your in there putting this machine together I'd be tempted to swap some better parts off your running loader. Especially if your steering gears, steering arm and well anything really. Would save you from some future expenses and not being able to source those parts. I have a second 6018 that was running and working until I had to steal the steering cylinder off it to put on my 6018bh while I was working it digging stumps and the seals let go. Then I was rebuilding the front axle on the bh and found some very worn spindles at the axle ends so now the 6018 doesn't have a front end underneath right now. But my bh has a nice and tight front end. I've since rebuilt the steering cylinder and have swapped them back. This winter I'll be dragging the 6018l back in for repairs. Just a thought.

Sent from my SM-S906U using Tapatalk

Well, it's a good idea except I plan to sell the good running loader as soon as this basket case is functional. Luckily the steering gear and arm look in really good shape. It's quite interesting to me how parts of this tractor, like most of the loader joints, are so badly worn and torn, while other parts are decent.

Today I got some more new 3/8 bolts for mounting the engine directly to the frame. I decided against any type of rubber mounts on this one. If the vibrations will be unbearable this issue will be revisited.

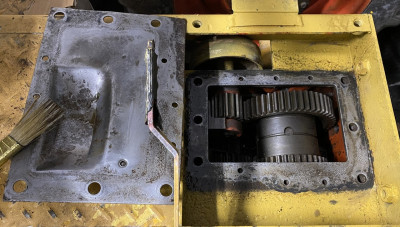

Also finally got to the rear end; got the cover off to assess things. Gears look fine, there's sludge at the bottom. The surface around the opening, on which the cover sits, had a lot of rust and grime. There is pitting too, just as there is on the cover itself. Scraped it well with a cutter and then wire brushed it. Applied rust treatment. I'll leave it open until the wheels can turn, when the gear box will get a good diesel treatment. Then I'll make a gasket and/or use gasket maker, to make sure no water makes it into the gear box again.

- Cleaned up the rust under the cover.

- Applied rust treatment on the underside the the cover and the surface it bolts on

To clarify, the reason for the rust treatment even after the wire brushing is because the wire brushing isn't perfect. The rust treatment will convert any little rust that's left into a black oxide which has a protective effect. Normally no water should make it this far though.

Re: Case 644 loader repairs

Posted: Sun Nov 27, 2022 10:38 pm

by JSinMO

Did you check the bolts that hold the differential halves together? With as much hard use as this tractor has seen It would be a shame to have a broken bolt walk out of the differential and break the case once you’re using it. You didn’t mention it in you post so I thought I’d ask.

If the rear cover and case are pitted I’d be looking for some type of gasket maker to take up the imperfections. Not sure if just a gasket would keep water out. I guess it depends on how bad the pitting is.

Looks like it coming right along. You’ll be running it around in no time!

Re: Case 644 loader repairs

Posted: Mon Nov 28, 2022 1:37 am

by Eugen

I did Jeff, the bolts are good. Thanks for the reminder!

I'm with you on the gasket maker. I was just wondering if I should use a gasket sandwiched between gasket maker.

As I mentioned the diesel bath in my last post it occurred to me that there's no need to do it later, can do it now. Raised the end on jacks and filled up the differential with diesel. For those of you with nothing better to do, allow me to entertain you with the gears slushing around in diesel duel.

https://vimeo.com/775676339

Re: Case 644 loader repairs

Posted: Mon Nov 28, 2022 4:14 am

by propane1

That was great entertainment Eugen. Thanks. Just what I needed at 5:00 am while I had nothing better to do. Hehehe.

For the cover on the gear box. I would use a gasket. And I would use a very very thin layer of your favourite gasket maker. I like to use a gray silicone that ford uses on there Diesel engines.

I wouldn’t worry about bolting the engine down solid. The older Ford LGT garden tractors had the base of the engine welded to the frame from the factory. I really think it’s the better way. Just my opinion.

Noel

Re: Case 644 loader repairs

Posted: Mon Nov 28, 2022 6:43 am

by DavidBarkey

Not to be a downer , but how the gasket and the surfaces between the frame and the trans axle ? My understanding is that the housing is on the bottom of the frame plate and the cover is on the top of the frame plate unlike the GTs which all bolts from underside . If I am wrong please correct me as I don't own one .