@Harry , as far as I can tell, the plating doesn't seem to be thick enough to affect the threads on these fittings. They screw in very smoothly. When the plating is finished the surface is a little rough, which I smoothed on the soft wire wheel.

@RoamingGnome In fact I just tried (again) electrolysis for rust removal, and every time I try it, it takes for ever, so I give up after a few hours.

These are the rust removal methods I tried and my impression of them.

Krud kutter: this is baed on phosphoric acid. My favourite for larger surfaces, or when I know I'll paint over. Really good, again, for not very deep rust. You're supposed to wipe it after a while, otherwise it leaves a white residue. If you wipe it after it ate the rust, the metal has a dark appearance, an oxide which is a good primer for painting. For USA, the Ospho product is like this but even better.

Evapo-rust: good for smaller parts, you leave the parts in the liquid for several hours. It does not affect the base metal, and the rust does go away. Very deep rust takes a lot longer or doesn't get affected. This liquid is water based, so it's not as evil smelling like muriartic acid.

Muriartic acid: this is really dangerous, but I have tried it (surprise). I don't really like it, and it does eat the base metal too. But it does de-rust, if left long enough.

Electrolysis: my experience with this is that it takes forever to get any rust off. Not my favourite, I don't have enough patience for it.

Wire wheel: I have many wire wheels that go on the drill or angle grinder. The rougher wheels are by far the fastest way to remove rust, but you know, it requires labour. Most of the time this is what I do, at least to get the thicker rust off, and then apply the Krud kutter for an hour or so, wipe that, and ready to paint when dry.

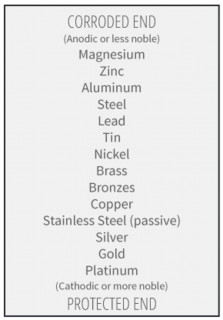

Regarding the exposure to elements, the unplated parts are steel. I think you know how steel reacts over time. The plated ones have a zinc layer. I know how zinc reacts to the elements, especially when it is on steel. To me it's the thickness of the plating that was in question. So last night I put a very rough wire wheel on the cordless drill and went at one of the parts. I had to put a real effort for several minutes to remove the plating on that area. So it's both thick and really well stuck to the metal, where the steel was clean. There's a another aspect of zinc on steel. You know they use on boats and inside boilers, zinc sacrificial anodes. Look at the series in this picture. The order is such that the metals above corrode before the metal below it, if they are both in contact with a corrosive agent (like dirty water). So, zinc on steel, in water, steel will corrode after the zinc is gone, if both are in contact with the same water at the same time. This is why even an imperfect plating with zinc will be much better for protection than no plating at all. Imagine, in a boiler, there is a large surface of steel on the inside, and one or two pieces of zinc, to protect it. Because the zinc attracts the corrosion to it. That's my understanding of it.